Manual Powder Coating Line for Metal Plates, Frames, Profiles

Email: services@colourspray.com

Whatsapp: 8618958052290

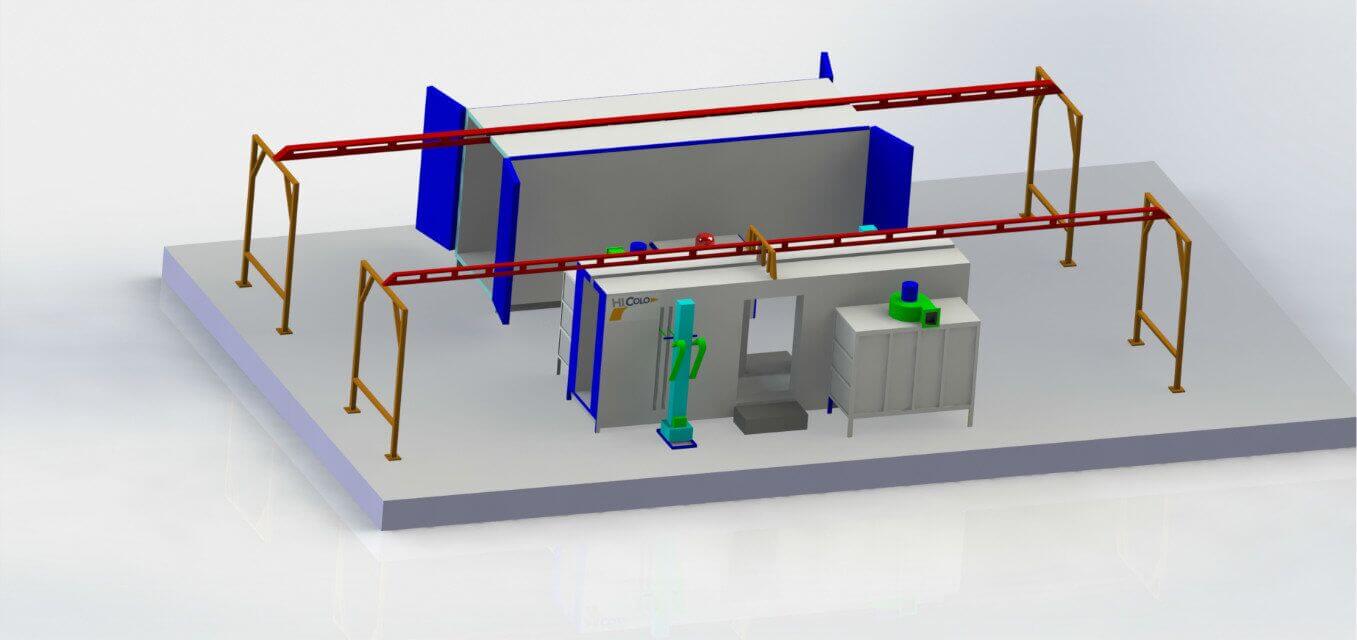

Manual Powder Coating Line for Heavy & Bulky Parts

COLO compact manual powder coating lines are designed to handle big or heavy parts in complex shape that requires precise manual coating, such as, metal frames, long plates, aluminum profiles, etc

It is configured with overhead track system which greatly reduce manual efforts for handling oversized and overweight parts, as well as pass through spray booth, curing oven and manual professional powder coating gun.

It is specially suits limited factory space and not enough budget comparing with automatic coating line.

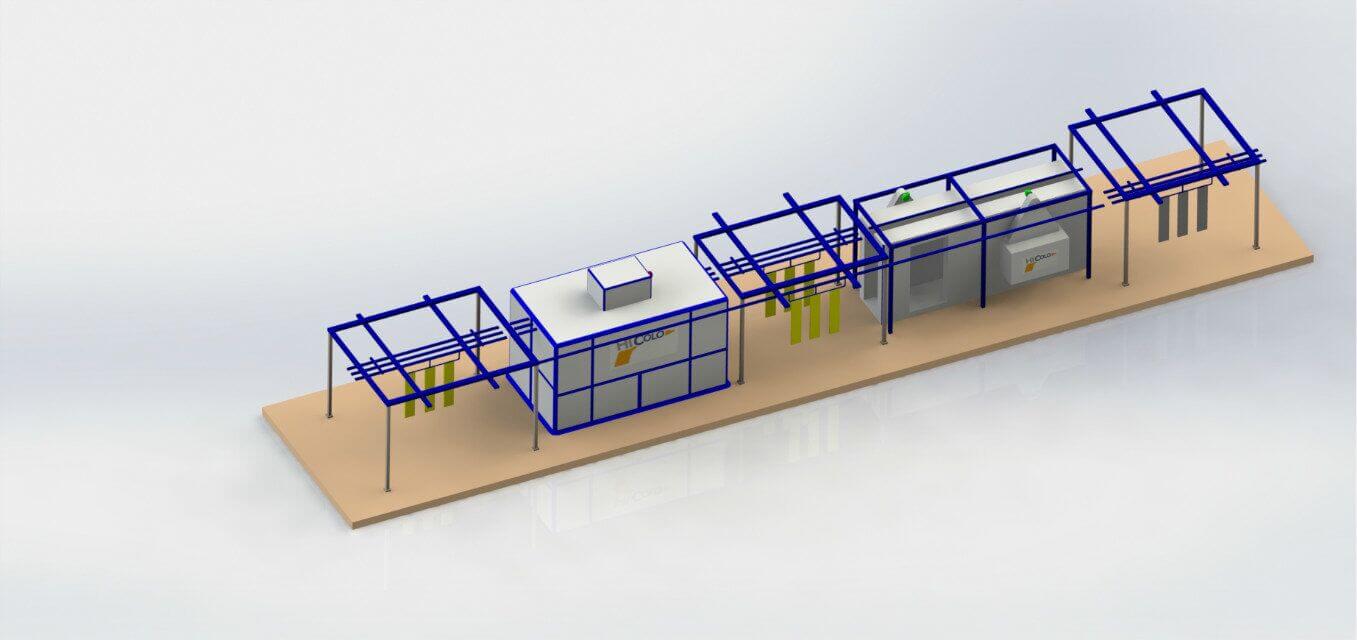

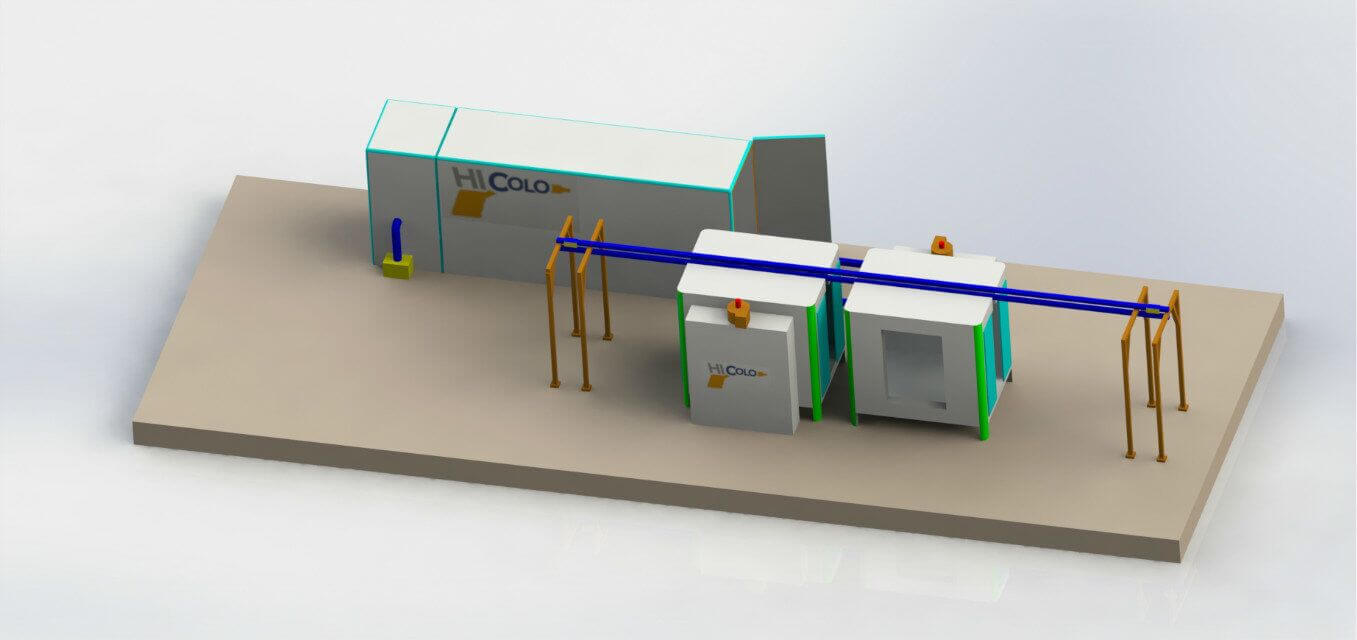

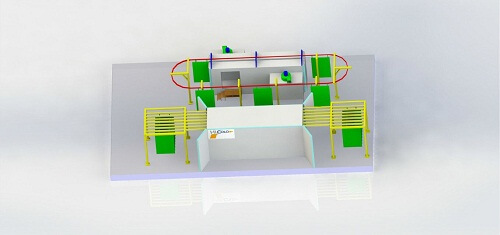

.webp) Manual Powder Coating Plant

Manual Powder Coating Plant Powder Coating Plant Drawing

Powder Coating Plant Drawing

Manual Powder Coating Line Applications

COLO Manual Powder Coating Line Advantages

1, Designed by COLO professional technical team, and manufactured on our own factory.

2, Save factory space, save labor efforts, save budget.

3, Excellent durability and reliability, minimum maintenance requirements

4, Worldwide customer cases, designed specially for you!

5, Maximize performance by applying various industrial parts.

6, Maximum flexibility, allowing adapting to differen kinds of workparts

7, Easy to handle loading and unloading operations, especially for heavy and big shape workparts

Manual Powder Coating Line Components

COLO-191S Intelligent Powder Coating Machine

The COLO-191S powder coating machine applies Digital Valve Controlled technology that allows precise setting of kv, current, powder output and dosing air, offers great accuracy and flexibility.

.webp?x-oss-process=image/resize,w_100/quality,q_100)

1. Easy to find the optimal data for each part, each powder, ensure powder coating application consistency.

2. Always applies right amount powders on parts' surfaces, ideal for coating complex parts with great powder savings.

3. The powerful 100kv electrostatic spray gun delivers highest transfer efficiency and maintain stable performance during long time work.

4. This model offers 3 pre-set application programs and 20 personalized programs, optimize coating quality, useful for both beginners and specialists.

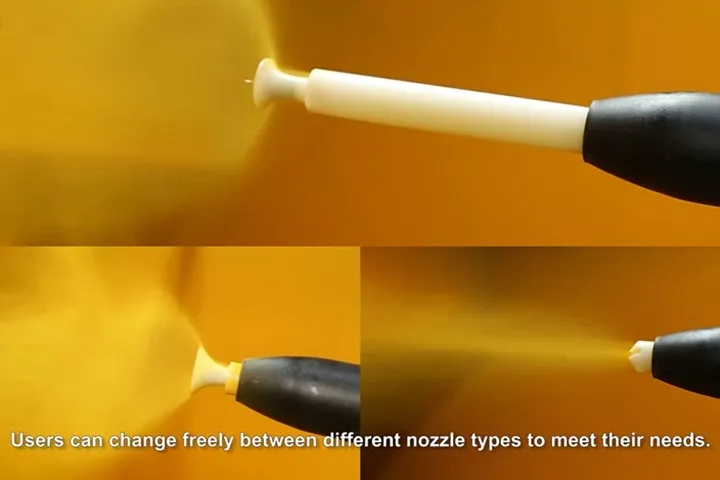

5. Provided with 3 types of nozzles for different spray patterns, including fan nozzles, round nozzles and extension nozzles.

Smart Controller

Smart Controller 100kv Spray Gun

100kv Spray Gun Nozzle Assembly

Nozzle Assembly

Walk-in Powder Coating Booth

The walk-in booth find use in batch system for aluminium profiles, large frames, long plates, big iron casting products, etc. As you can walk into the booth for precisely manual spraying, complex shapes will be perfectly coated.

-副本.webp?x-oss-process=image/resize,w_100/quality,q_100)

1. The front doors can be closed during powder spraying process, creating a clean, dustless workshop, with energy-saving lights inside the booth cabin.

2. Powder reclaim is achieved by filter recovery stages, which is combined with enough quantity of high precision filters, reach 98% powder recycling rate.

3. Filter cleaning is automatically done through pulse solenoid valves, thus filter life is extended.

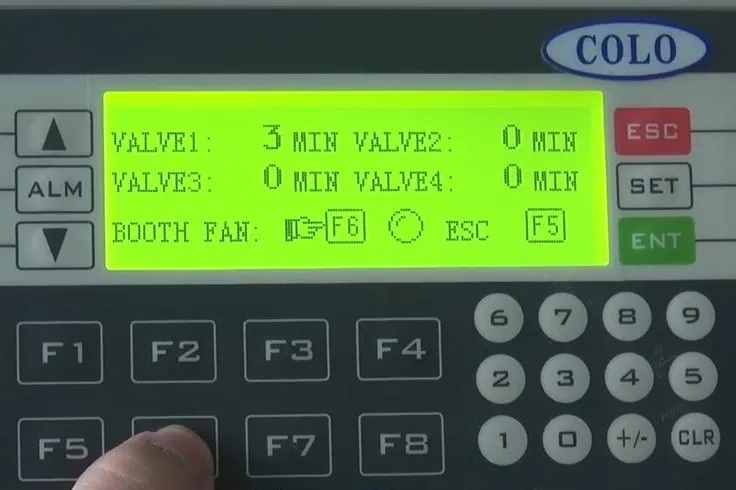

4. PLC provides all the functions you need, control the fan working, set interval and time of pulse jet for filter cleaning.

5. We use aluminium fans which are durable, safe and quite. Fan is installed at the top of filter room that saves shop space

with doors closed

with doors closed filter recovery stage

filter recovery stage PLC control

PLC control

Track Type Powder Coating Curing Oven

The powder coating oven can be designed for gas, diesel, electric heating as actual conditions, longer length we recommended gas/diesel curing oven, while gas heating is more clean and environmental.

.webp?x-oss-process=image/resize,w_100/quality,q_100)

1.The overhead tracks allows carrying heavy materials and smoothly moved by manual with less efforts, the quantity of the tracks can be customized.

2. High efficiency gas burner heating enables rapidly raise to the required temperature, save your time every day.

3. A powerful and durable circulation fan makes even temperature in inner chamber ensure high quality curing results.

4. Oven material is 100mm thickness rock wool board of the interlayer with durable color steel skin and heat-resistent galvanized inner wall, keeping a long time heat preservation.

5. Easy-to-use PLC control system provides a precise heating process by setting accurate heating time and temperature.

overhead tracks

overhead tracks Riello gas buriner

Riello gas buriner PLC Control

PLC Control

Manual Powder Coating Line Application Case

This powder coating line is specially designed for our Australia customer at year 2020, and is popular now amoung worldwide customers. The customer has provided a lot of site photos and videos for praising of our project as it has been perfectly working for 5 years.

According to object parameters, factory size, We have designed a variety of manual and automatic powder coating lines for global customers, pls feel free to leave your production needs and we will design specially for you!

Oversea installation is available. Contact now!

Manual Powder Coating Line Different Designs

Manual Powder Coating Line 1

Manual Powder Coating Line 1  Manual Powder Coating Line 2

Manual Powder Coating Line 2

Manual Powder Coating Line 3

Manual Powder Coating Line 3  Manual Powder Coating Line 4

Manual Powder Coating Line 4

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)