.jpg?x-oss-process=image/resize,w_100/quality,q_100)

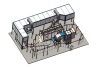

Automatic Powder Coating Line for Small Parts

Email: services@colourspray.com

Whatsapp: 8618958052290

Automatic Powder Coating Line for Small Parts

This automatic powder coating line is designed for high output of small accessories, thus it could fit compact space factory. It is configured with Automatic coating guns and equipment, cyclone automatic spray booth and tunnel oven

Workparts movement by overhead conveying system. Powder spraying by automatic equipment ensures uniform powder film thickness, powder recycling by cyclone system and powder feed center. A continuous tunnel oven curing workparts ensures efficiency,

This automatic powder coating line is specially designed for our Australia customer for the application of springs in high output and superior quality.

Powder Coating Booth

Powder Coating Booth Automatic Powder Gun & Powder Feed Center

Automatic Powder Gun & Powder Feed Center powder curing tunnel oven

powder curing tunnel oven

1. Automatic Powder Coating Equipment

Reciprocator Spray Gun System:Driven by frequency motor, reciprocators carry spray guns to move up and down in programmed stroke and speed. The precise and stable motion achieves uniform quality coating.

Central Control Cabinet: A central cabinet combines the all the gun controllers for integrated setting of parameters. Ensures reliability and controllability.

Powder Feed Center: Designed for continuously, uniformly, quantificationally feed the powder to the spray gun, applied in an automatic powder coating line to improve quality and efficiency. Automatic cleaning of spray guns, powder pipes, powder pumps increase efficiency especially in frequent color change line.

2. PP Plastic Automatic Powder Coating Booth:

It is designed with automatic coating stations for the reciprocators and manual station for repair coating. Cyclone reccovery is necessary for fast color change demands. After filter unit is to capture superfine powder particles ensure the vented air is clean.

The automatic powder coating booth is constructed with pp plastic booth chamber and stainless steel cyclone. As the booth wall is made of anti-static plastic it does not attract powders which minimizes powder accumulation on the surface. It is the best choice for quick color change and high powder recovery demands.

Booth floor is designed with air knife and flap recovery system, effectively transfer sprayed powder from the booth floor to recycling system, increase powder utilization

3. Powder Coating Tunnel Oven

Powder Coating Curing tunnel is designed for continuous operations. The product painted in these furnaces which are used in conveyor automatic powder coating line and is constantly processed under desired temperature and time.

Workparts automatically enter the oven and move by overhead conveyor, when they come out from the exit of the oven, they finish the curing process in a fitted time

Tunnel oven may be manufactured in various types depending on the lack of space to be installed or the conveyor speed. Maximum painting efficiency is obtained with high capacities by means of this system.

Automatic Powder Coating Line Specifications for Reference

| Design Principle | ||

| Processed Workparts | Springs | |

| Working Area | L10m x W15m x H6m | |

| Powder Spray Booth | ||

| Type | Automatic Type | |

| Powder Spray Booth Size: | W1280*H1500*L4000mm, Opening: W680xH1500mm | |

| Powder Recovery | Multi-cyclone | |

| Cartridge Filter System | 325x600mm, 18pcs. | |

| Fan Motor | 11kw, 7000m³/h | |

| Spray Booth Material: | PP Plastic & Stainless Steel | |

| Powder Coating Equipment | ||

| Automatic Powder Guns | COLO-191S, 8 pcs | |

| Manual Powder Guns | COLO-191S, 2 pcs | |

| Central Contral Cabinet | 2 sets | |

| Powder Coating Reciprocator | COLO-2000D, 2sets, 1.5m stroke | |

| Powder Sieving & Recyling | COLO-6000D Powder Feed Center, 1 set | |

| Powder Curing Oven | ||

| Type | Automatic Tunnel Type | |

| Powder Curing Oven Size: | W2880 X H3000 x L14200 mm | |

| Heating Source | Gas | |

| Heating Time & Temperature | Warm-up time: 15-30 min. (180° C), Max.250° C | |

| Material | 100mm thick rockwool board Interlayer | |

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg)

-副本.webp?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)