Ground Rail Automatic Powder Coating Line for Thermal Cups

Email: services@colourspray.com

Whatsapp: 8618958052290

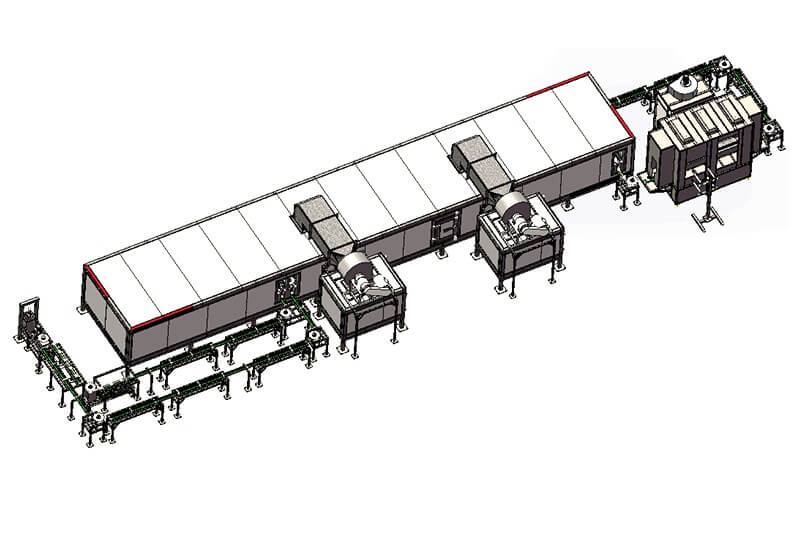

Ground Rail Automatic Powder Coating Line for Thermal Cups

The ground rail coveying powder coating line is specially designed for cup, pot or bottle shape metal products which are not able to be suspended by overhead conveyors. COLO built this automatic powder coating plant for our Algeria customer for their application of themal cups,

Ground Rail Automatic Powder Coating Line Working Process

1. Pre-heat Themal Cups by Tunnel Oven 2 Powder Spraying by Automatic Powder Coating System & Booth 3 Powder Curing by Curing Oven (the same oven for pre-heating)

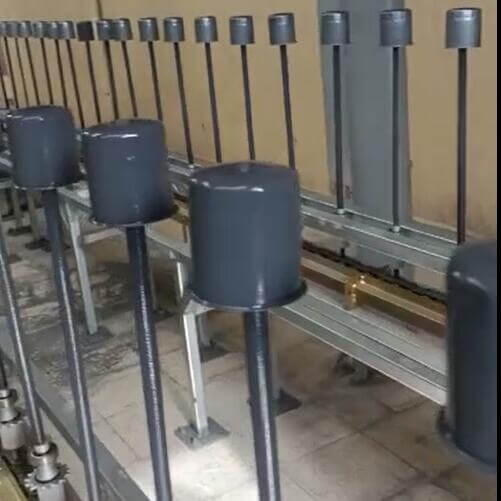

Automatic Powder Coating Guns & Booth System

Automatic Spray Guns & Control Cabinet: A central cabinet combines all the gun controllers for integrated setting of parameters. Ensures reliability and controllability. Our intelligent powder coating gun is designed for perfectly coating different parts, whether flat panels or complex shapes.

Automatic Powder Sieving & Recycling System: the system sieves and recycle large quantities of used powders without disturbing your online coating process, at the same time mixing with fresh powders for continuouse feeding, substantially eliminate wastage.

utomatic Powder Coating Booth:Designed with working stations for automatic coating guns. and filter recovery stage for effectively collects powder overspray, ensures clean working environment and reduce powder waste. The automatic spray booth is controlled via PLC, which is easy for operation.

Tunnel Oven for Pre-heating & Powder Coating Curing

The cups will be first enter to th tunnel oven for pre-heating , then are transported to powder spraying station, finaly back to the tunnel oven for curing forming a durable, uniform coating film.

Tunnel oven are designed for continuous operations. The coated products in these furnaces which are used in conveyor automatic facilities is constantly processed under desired temperature and time. Maximum painting efficiency is obtained with high capacities by means of those systems.

Ground Rail Automatic Powder Coating Line Specifications

| Powder Spray Booth | |

| Powder Spray Booth Size: | With1120 * Height1500 * Depth2900mm |

| Powder Recovery | Cartridge Filters, 4pcs |

| Fan Motor | 1 set, 3kw 4500m3/h |

| Spray Booth Material: | SPCC/=1.5mm |

| Powder Coating Equipment | |

| Automatic Powder Guns | COLO-800D Automatic Type, 4pcs. |

| Output High Voltage | Max. 100kv |

| Central Contral Cabinet | 1 set |

| Drying/Curing Oven | |

| Drying/Curing Oven Size: | With2300 * Height1100 * Depth14600mm |

| Heating Source | Electric |

| Heating Power | 252KW, 84 pcs heating tubes of 3kw |

| Heating Time & Temperature | Warm-up time: 15-30 min. (180° C), Max.250° C |

| Circulation Fan | 5.5kw, 2sets |

| Ground Rail | |

| Ground Rail Length | 125m |

| Round Rail Conveying Speed | 25m/min |

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

-副本.webp?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)