.jpg?x-oss-process=image/resize,w_100/quality,q_100)

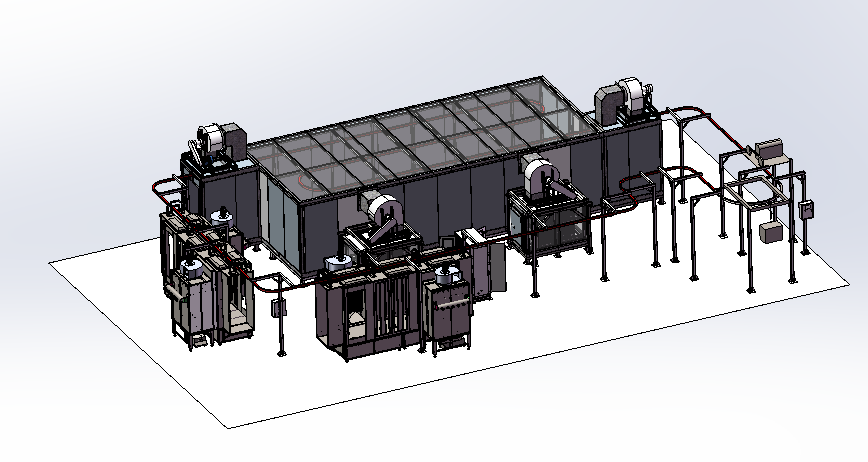

Automatic Powder Coating Painting Line (2 sets Automatic Booth Systems)

Email: services@colourspray.com

Whatsapp: 8618958052290

Automatic Powder Coating Painting Line for 2 Colors

This automatic powder painting line is designed according to the Mexico customer's requirements for superior efficiency and high output. It is configured with 2 automatic spray booths ans 2 powder coating systems, especially effective for application of 2 colors. Thus, without cleaning during color change greatly reduces downtime.

The customer applies this powder coating plant to the internal and external spraying of fan cover, the output can reach 300 pieces per day. Workparts movement by overhead conveying system. Powder spraying by automatic equipment ensures uniform powder film thickness, powder recycling by sieving system. A continuous curing oven ensures efficiency.

We design and manufacture automatic powder coating lines based on customer's requests, such as product size, production capacity, factory size, gas heating source, etc. According to different requests, there are many types of design drawing for your choice.

1. Automatic Powder Coating Equipment

Reciprocator Spray Gun System:Driven by frequency motor, reciprocators carry spray guns to move up and down in programmed stroke and speed. The precise and stable motion achieves uniform quality coating.

Central Control Cabinet: A central cabinet combines the all the gun controllers for integrated setting of parameters. Ensures reliability and controllability.

Powder Sieving & Recycling System: Designed for continuously, uniformly, quantificationally feed the powder to the spray gun, applied in an automatic powder coating line to improve quality and efficiency. Automatic cleaning of spray guns, powder pipes, powder pumps increase efficiency especially in frequent color change line.

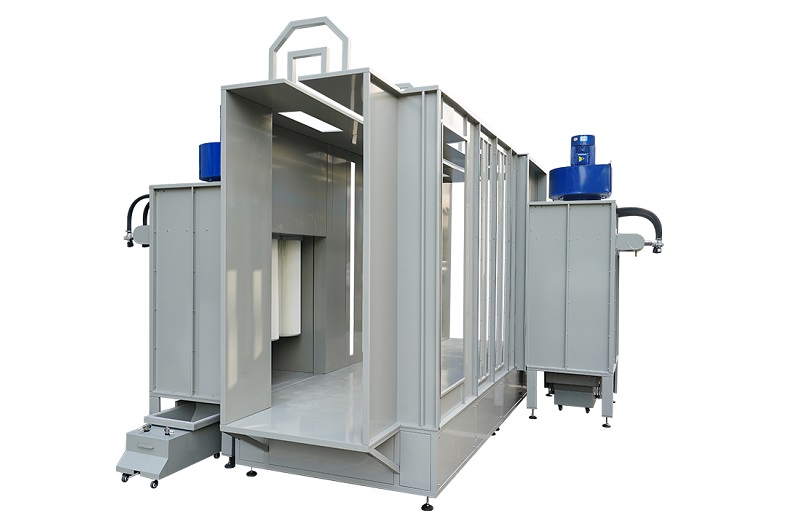

2. Automatic Powder Coating Booth:

It is designed with automatic coating stations for the reciprocators and manual station for repair coating.

Double filter stage recovery systems effectively capture oversprayed powder, 0.1micron high precision filters ensures only particle-free air discharged outside.

3. Powder Coating Tunnel Oven

Powder Coating Curing tunnel is designed for continuous operations. The product painted in these furnaces which are used in conveyor automatic powder coating line and is constantly processed under desired temperature and time.

Workparts automatically enter the oven and move by overhead conveyor, when they come out from the exit of the oven, they finish the curing process in a fitted time

4. Powder Coating Overhead Conveyor System

A complete overhead conveyor system includes, rails (or I beam), chains, drive unit, hangers, trolleys, tension device, etc We provide conveyor systems based on your specific products, designs varies from product weight, size and even the shape.

Our conveyor system can endure the high temperature when it pass through the curing oven.

Automatic Powder Coating Line Specifications for Reference

| Design Principle | |

| Processed Workparts | Fan Motor Cover |

| Production Capacity | 300 pieces per day (8 hour) |

| Required Working Area | L21.5m x W13m |

| Powder Spray Booth( 2 sets) | |

| Type | Automatic |

| Powder Spray Booth Size: | W1120*H2000*L4000mm, Opening: W800xH2000mm |

| Powder Recovery | Cartridge Filter Stages |

| Cartridge Filter System Spec | 325x900mm, 12pcs. (for each booth) |

| Fan Motor | 5.5kw, 7000m³/h, 2 sets (for each booth) |

| Spray Booth Material: | Powder Coated Steel |

| Powder Coating Equipment | |

| Automatic Powder Guns | COLO-191S, 16 pcs |

| Manual Powder Guns | COLO-191S, 4 pcs |

| Central Contral Cabinet | 2 sets |

| Powder Coating Reciprocator | COLO-2000D, 4sets, 2m stroke |

| Powder Sieving & Recyling | COLO-3000-S Automatic Powder Sieving System, 2 sets |

| Powder Curing Oven | |

| Type | Automatic Tunnel Type |

| Powder Curing Oven Size: | L8800 X W4300 x H2430 mm |

| Heating Source | Electric |

| Heating Power | 3kw, 180pcs |

| Heating Time & Temperature | Warm-up time: 15-30 min. (180° C), Max.250° C |

| Material | 100mm thick rockwool board Interlayer |

| Powder Coating Conveyor System | |

| Type | Overhead Type |

| Total Length | 74m |

| Hanging | 2 point handing |

| Chain Type | UH-5075-S, Single Point Loading Capacity: 35kgs |

| Speed | 1.5m/min, adjustable |

| Other Components | Drive unit 1set, tension system 1set, urgent stop unit 4set, |

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg)

-副本.webp?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)