Manual Powder Coating Line (Pass Through Booth & Track Oven)

Email: services@colourspray.com

Whatsapp: 8618958052290

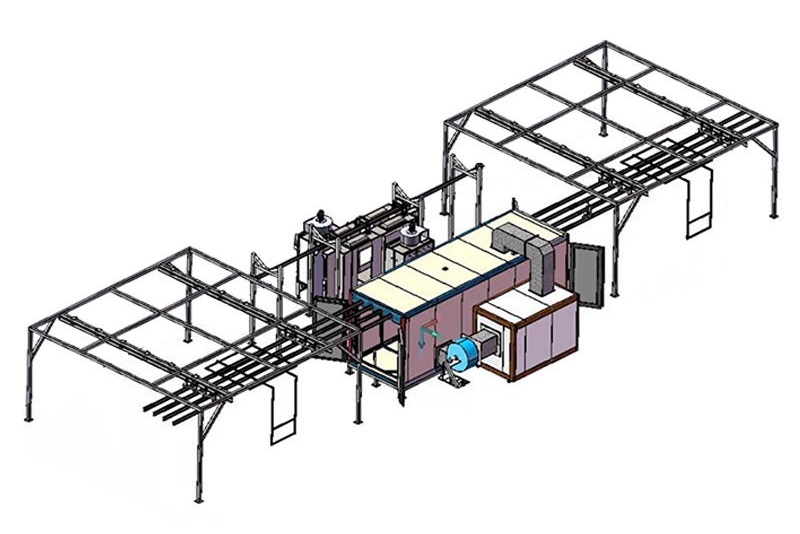

Manual Powder Coating Line with Cross Pull Track System

This powder coating line is specially designed for manual coating of aluminum profiles and other long thin metal parts, whose overhead track system allows manually moving big batch heavy materials with less efforts. And it is ideal for handling complex shaped parts which requires extreme high requirement manual coating, also suitable for first timer applicators.

Manual Powder Coating Line Application

This powder coating line is widely used for continuous batch production with higher output using less efforts, based on manual system with horizontal pull conveyor system, includes pass thru powder coating booth with two operating position at both sides, and tunnel ovens for curing, as well as manual powder painting machines.

Manual Powder Coating Line Customer Case (in South Korea)

Manual Powder Coating Horizontal Line Configurations

COLO-191S Intelligent Powder Coating Machine

1. Digital valve controlled technology that allows precise setting of kv, current, powder output and dosing air, offers great accuracy and flexibility. It is specially meet the demands of coating complex parts with great powder savings.

2. The powerful spray gun with 100kv cascade delivers highest transfer efficiency and maintain stable performance during long time work.

3. This model offers 3 pre-set application programs and 20 personalized programs, optimize coating quality, useful for both beginners and specialists.

4. A clear and easy to use LCD interface facilitate every user to take advantage of these powerful technologies.

| Model | COLO-191S |

| Power Range | 220V/110V (customized) |

| Frequency | 50-60Hz |

| Gun Weight | 500g |

| Temperature Range in Use | -10 ℃+50 ℃ |

| Rated output voltage | 24VDC |

| Input Voltage | - 200kv |

| Maximum output current | 180Ua(max) |

| Maximum output voltage | 0-100KV (adjustable) |

| Maximum powder injection | 600g/min |

| Polarity | negative (-) |

COLO Pass Thru Powder Coating Booth

1. Dual station powder spray booth, parts enter the booth through the overhead track, then pass the working stations to receive the powder coating from the dual stations.

2. Powder reclaim is achieved by a recovery stage, which is combined with several pieces of high precision filters, reach 98% powder recycling rate.

3. Filter cleaning is automatically done through pulse solenoid valves, thus filter life is extended.

4. PLC provides all the functions you need, control the fan working, set interval and time of pulse jet for filter cleaning.

5. We use aluminium fans which are durable, safe and quite. Fan is installed at the top of filter room that saves shop space

| Type | Pass Thru |

| Inner Size | L4m x W1.1m x H1.8m |

| Opening Size | W0.5m x H1.82m |

| Material | SPCC/t=1.5mm |

| Bottom Frame | 8# square tube |

| Booth Inner Frame | 8# square tube |

| Recovery System | Filter Cartridge (10pcs) |

| Fan Motor | 4kw, 2sets |

| Air Flow | 5000m^3/h |

Powder Coating Curing Oven

.jpg?x-oss-process=image/resize)

1. The powder coating oven can be designed for gas, diesel, electric heating as actual conditions, longer length we recommended gas/diesel curing oven, while gas heating is more clean and environmental.

2. High efficiency heating element enables rapidly raise to the required temperature, save your time every day.

3. A powerful circulation fan makes even temperature in inner chamber ensure high quality curing results.

4. 100mm thickness rock wool board of the interlayer, keep long time heat preservation.

5. PLC panel control the working of fan, setting the heating time and temperature.

| Type | Gas Curing Oven |

| Working Dimension | Width 1.8m x Height 2.1m x Depth 7m |

| Insulation | t=100mm |

| Hemming | SGCC/t=1.5mm |

| Bottom Frame | 8# Square Tube |

| Inner Frame | 8# Square Tube |

| Gas Burner | 300,000 kcal/h, RIELLO brand |

| Fan Motor | 7.5kw, 1 set |

| Air Flow | 8000m^3/h |

We offer custom sizes and designs of powder coating system based on your products and requirements , oversea installation is available. Contact now!

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.jpg)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)