-副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Semi-automated Powder Coating Line for Metal Chairs (built in Ethiopia)

Email: services@colourspray.com

Whatsapp: 8618958052290

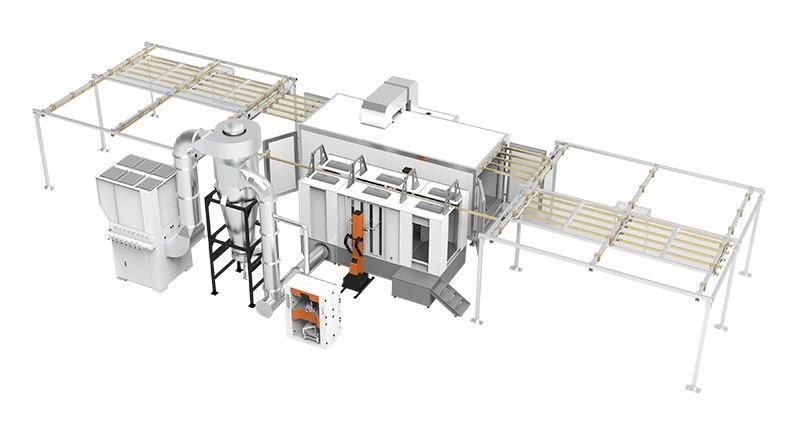

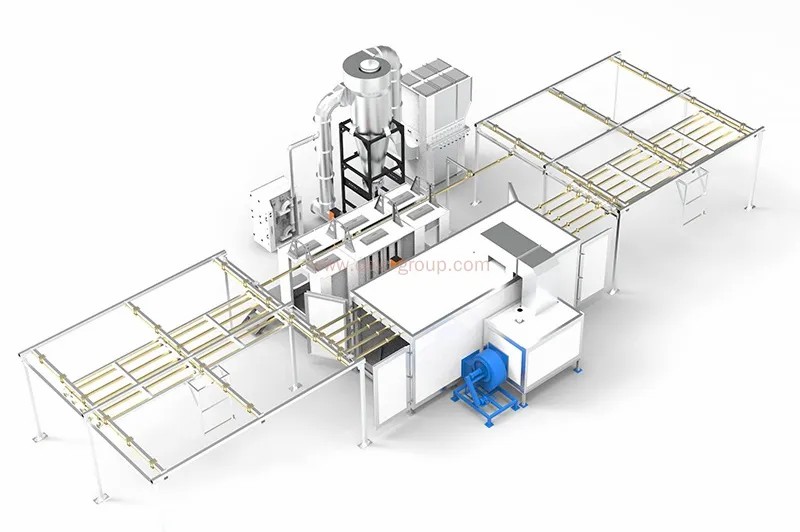

Semi-automated Powder Coating Line Design

The semi-automatic powder coating line is specially designed for big shape or heavy workparts requires high volume production, but with not enough budget and factory space, configured a cyclone automatic powder booth requested for fast color change demands. The powder coating line is ideal for powder coating aluminum profiles, metal frames, steel chairs and other furniture products, etc.

Semi-automated Powder Coating Line Customer Case - in Ethiopia

How semi-automatic powder coating line works?

1) Operator moves the loaded workparts with tracks into the station in front of the powder booth.

2) Manually moves the workparts towards to the powder booth overhead conveyor.

3) The workparts will be automatically transported once enter the conveyor

4) There are reciprocating guns at both sides of the powder booth for efficient automatic powder coating

5) After automatic powder coating, the workparts exit out automatically

6) Operator horizontally pulls the workparts to the station in front of the curing oven

7) Manually move the workparts in and out of curing oven.

Semi-Automatic Powder Coating Line Components

COLO-800D Automatic Powder Coating Equipment

1. It is the ideal entry into automatic series production offering quality finishes and great powder savings.

2. Multi controllers of automatic powder coating gun installed on a central cabinet, with compact design and simple operation.

3. The cabinet can be tailored to customer's demands, allows to install Max. 24 control units.

4. COLO-800D automatic powder coating machine is one of the most suitable solution for coating line, effective, relible, cost-saving.

5. The reciprocator driven by frequency motor, speed and stroke adjustable. The sturdy construction could adapt to continual load everyday.

COLO Conveyor Powder Coating Booth

1.Mono cyclone achieves the overspray recycling rate upto 98%, whose self-cleaning mechanism maximizes efficiency during color change, and greately saves powder.

2.High precsion and long lifespan filters as the secondary recovery system after cyclone, capture the dust even 0.1 micron, ensure clean air discharged to the workshop

3.With automatic coating platform for reciprocating guns, and an open manual coating platform, gives convenience for easy inspection or re-coating large workpieces in complex shapes.

4.Our mono-cyclone automatic powder booth is constructed with plastic booth wall, such anti-static materials increase powder recovery efficiency.

COLO-6200 Powder Management Center

The newly-developed powder management center is an efficient and space-saving solution for powder recycling and feeding needs in automatic powder coating line, has the following highlights:

1. Allows directly placing the original powder package into the bottom funnel, much more flexible for color change.

2. Automatic cleaning of hopper, suction tube, injectors, pump, hoses and spray guns, maximize efficiency during color change.

3. Closed powder circuit prevents overflow to ensures a clean working environment as well as save powders.

4. Has a very compact design and can be flexibly adapted to any system layout.

Track Powder Coating Curing Oven

1. The powder coating oven can be designed for gas, diesel, electric heating as actual conditions, longer length we recommended gas/diesel curing oven, while gas heating is more clean and environmental.

2. High efficiency heating element enables rapidly raise to the required temperature, save your time every day.

3. A powerful circulation fan makes even temperature in inner chamber ensure high quality curing results.

4. Construced with 100mm thickness rock wool board, ensures minium temperature dropping.

5. PLC control system provides an easy and accurate heating process, digitally setting the heating time and temperature.

COLO Semi-automatic Powder Coating Line Benefits

1) Space-saving. Allows small workshop to build the aluminum profile (long workparts) powder coating project

2) Maximize production rate. The automatic powder coating system with a section of automatic conveyor greatly increase processing efficiency

3) Less labor cost. The horizontal pull track system, the automatic powder coating system with conveyor, minimize the manual efforts.

4) Cost-saving. the combination of manual and automatic operation system will costs less comparing with a fulll automatic coating line.

5) Custom Available. The professional and experienced team of COLO will custom booths, ovens and systems specially for your products!

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

-副本.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)