Automatic Powder Coating Line for Fence (built in Russia)

Email: services@colourspray.com

Whatsapp: 8618958052290

Automatic Powder Coating Line for Fence (Built in Russia)

We design and manufacture electrostatic powder coating lines based on customer's requests, Automatic powder coating lines is widely used for continuous metal parts finishing, workparts will be transported by conveyor system to the powder booth receiving unifom powder spraying by reciprocating gun system, then will be transforted to a curing tunnel,

COLO Designed and built an automatic powder coating line for Russian Customer for their Fences & Gates。

1. Automatic Powder Coating Equipment

Automatic Spray Guns & Reciprocator: Driven by frequency motor, reciprocators carry spray guns (up to 20pcs) to move up and down in programmed stroke and speed. The precise and stable motion achieves uniform quality coating.

Central Control Cabinet: A central cabinet combines the all the gun controllers for integrated setting of parameters. Ensures reliability and controllability. Our powder coating gun controller is intelligent and easy-operated to handle all shapes of workparts.

Powder Recycling System Sieving Machine: Automatic sieving machine is an economical solution for powder feeding, automatic conveying and sieving recycled powders to mix with fresh powders, continuous feeding them to the system

2. Automatic Powder Coating Booth:

Designed with automatic coating stations for the reciprocators, as well as a manual station for repair coating. This is a filter recovery powder booth which is ideal for single color application, Cyclone is necessary for fast color change demands. Booth material can be made by Coated Steel Plate, or Stainless Steel and PP Plastic or stainless steel to improve recovery and cleaning efficiency.

5.Powder Coating Curing Tunnel

Curing tunnel are designed for continuous operations. The product painted in these furnaces which are used in conveyor automatic facilities is constantly processed under desired temperature and time. It may be manufactured in various types depending on the lack of space to be installed or conveyor speed. Maximum painting efficiency is obtained with high capacities by means of those systems.

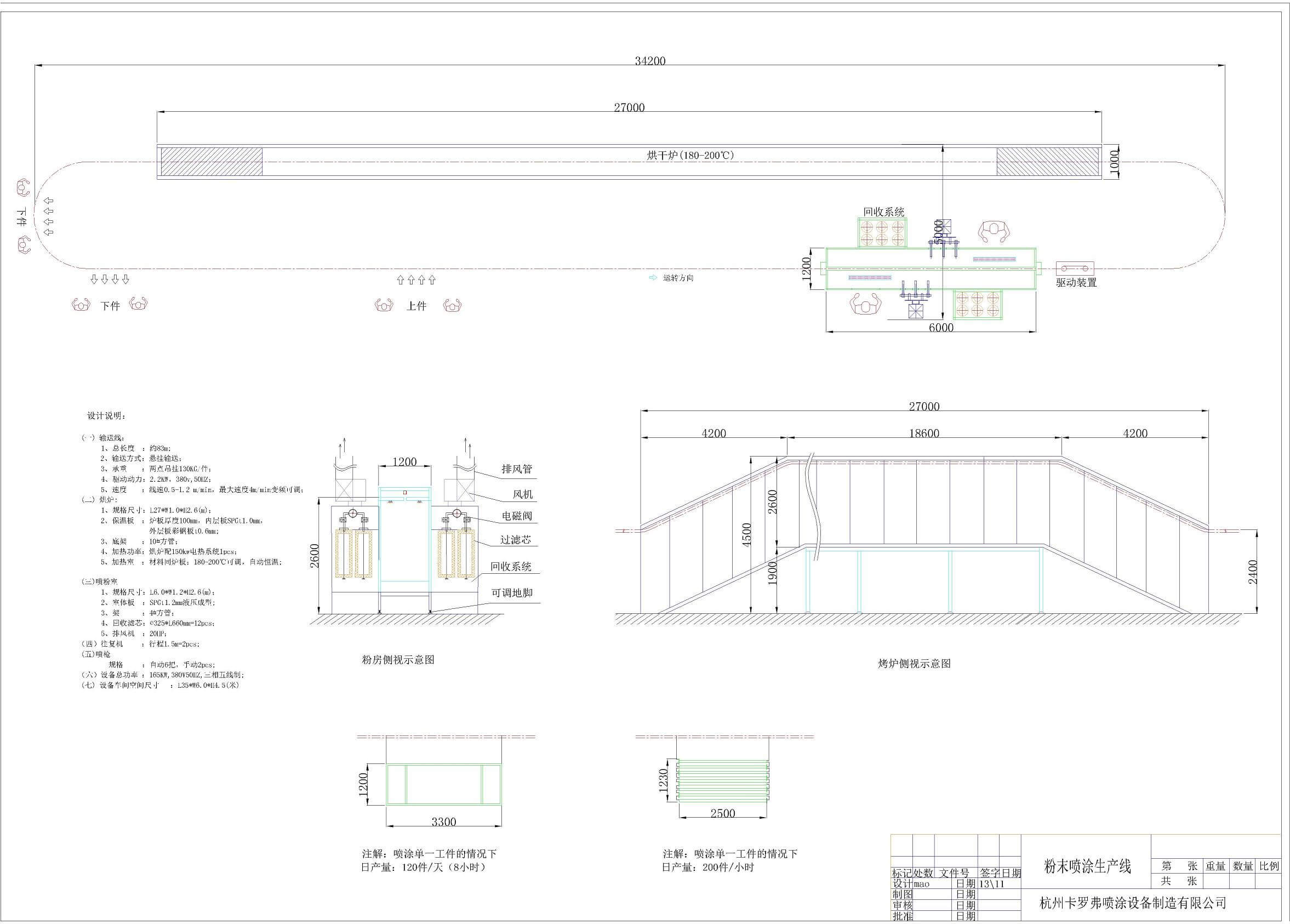

Automatic Powder Coating Line Specifications for Reference

| Design Principle | ||

| Processed Workparts | Items 1: Aluminum, Steel, Max Size: L2500×Dia72mm, 30 kgs/piece Items 2: Aluminum, Steel, Max Size: L3300×W1200×H120mm,130kgs/piece |

|

| Working Area | L35000×W6000×H4500mm | |

| Powder Spray Booth | ||

| Type | Automatic Tunnel Type | |

| Powder Spray Booth Size: | L6*W1.2*H2.6m | |

| Powder Recovery | Filters | |

| Cartridge Filter System | 325x600mm, 12pcs. | |

| Fan Motor | 5.5kw | |

| Spray Booth Material: | SPCG/=1.5mm | |

| Powder Coating Equipment | ||

| Automatic Powder Guns | 6 pcs | |

| Manual Powder Guns | 2 pcs | |

| Central Contral Cabinet | 2 sets | |

| Powder Coating Reciprocator | COLO-2000D, 2sets, 1.5m stroke | |

| Powder Curing Oven | ||

| Type | Automatic Tunnel Type | |

| Powder Curing Oven Size: | L27m x W1m x H2.6m | |

| Heating Source | Electric | |

| Heating Power | 150kw | |

| Heating Time & Temperature | Warm-up time: 15-30 min. (180° C), Max.250° C | |

| Material | 100mm rockwool board Interlayer; SPGt1.0mm innerwall; color steel 0.6mm skin | |

| Overhead Conveyor System | ||

| Total Length | 83m | |

| Overhead Conveying Speed | 0.5-1.2m/min, Max.4m/min (adjustable) | |

| Loading Capacity | double point hanging: 130kgs | |

| Drive power: | 2.2kw; | |

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)