Gas/Electric Powder Coating Oven Design

COLO is a 14 years professional manufacturer and designer of various powder coating ovens, such as electric curing ovens, gas/diesel curing ovens based on heating technology. Our standard models range from small batch powder coating ovens to large curing ovens for big elements or high output. Custom coating ovens are available for conveyorized coating systems in manual or automated production lines.

-

COLO-1688 Small Electric Powder Coating Oven

COLO-1688 Small Electric Powder Coating Oven

-

COLO-1864 Electric Batch Powder Coating Ovens

COLO-1864 Electric Batch Powder Coating Ovens

-

COLO-1732 3meter Batch Powder Coating Ovens

COLO-1732 3meter Batch Powder Coating Ovens

-

COLO-3210 Gas Powder Coating Batch Oven

COLO-3210 Gas Powder Coating Batch Oven

-

COLO-5219 Big Batch Powder Coating Gas Oven

COLO-5219 Big Batch Powder Coating Gas Oven

-

Powder Coating Oven with Overhead Rails

Powder Coating Oven with Overhead Rails

-

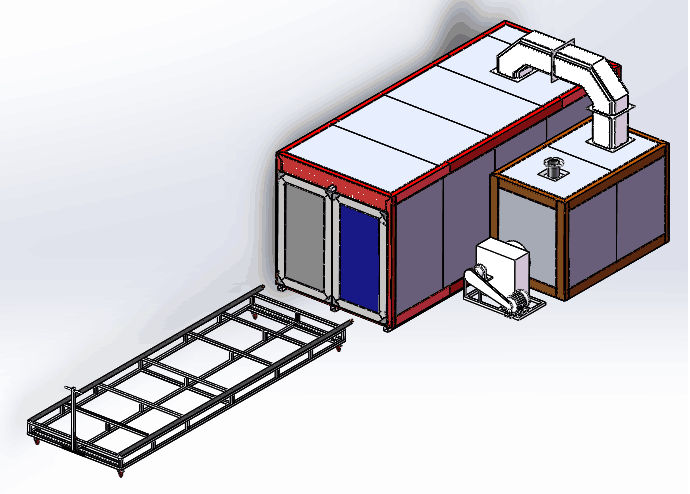

Powder Coating Tunnel Oven for Automatic Line

Powder Coating Tunnel Oven for Automatic Line

COLO Powder Coating Oven Configurations & Features

PLC Control System

PLC Control System

PLC Control system provides an easy and accurate heating process. It offers all features you need, the keyboard and LED display allows you to set and read precise temperature as well as duration you required. Other buttons functions such as power on/off, fan starting, emergency stop, etc.

Circulation Fan

Circulation Fan

It circles hot air which generated by heating elements through the entire space of curing chamber, ensure uniform heat distribution whose temperature durability is less than 5℃, thus offering excellent quality finish. Fan for small ovens will be installed on the bottom of curing oven to save space. Fan for larger ovens is specially designed, built with insulation material to reduce heat loss.

Electric Heating Tube (for Electric Powder Coating Oven)

Electric Heating Tube (for Electric Powder Coating Oven)

Heating Tubes are the heating source for electric powder coating oven, each oven are installed with several pieces of tube, quantity increases as the oven dimension increases. The heating tubes can be installed in the sides or bottom of inner chamber, it is depends on actual requirement.

Circulation Fan

Circulation Fan

Comparing with other burners, Italy RIELLO burner makes fully burning of fuels and requires less time to reach to high temperature. Energy-saving, time saving. We can provides you Gas/Diesel burners.

Heating Exchanger (for diesel curing oven)

Heating Exchanger (for diesel curing oven)

As burners fully burns the fuels at the same time warm-up the heat exchanger. The heat exchange is made of seamless 310S stainless steel pipe these pipes are in high temperature thus to heat the air. Hot air are than transported to curing chamber through the fan. This heating method creates clean hot air to curing powder-coated parts, results quality finishes.

Circulation Fan

Circulation Fan

Insulation: 100mm thick rock wool layer maximizes heat preservation performance

Inner Wall: t=1mm galvanized wall, heat-resistant. density:12

Outer Wall: t=0.7mm color steel sheet, wear-resistant and longer life.

Why Choose COLO Powder Coating Ovens?

We use advanced heating technology to get each powder oven to curing temperature faster and requires less fuel to cure powder coated parts, which saves your time and reduces your operating costs every day. The high quality materials and imported components consist of a longlife, efficient, reliable powder coating oven.

For 14 years, we've been researching and upgrading our powde coating ovens to meet various demands of woldwide customers and ensure each appliance produces high-quality, long lasting powder finishes.

We offer complete finishing solutions from pretreatment cleaning to powder spraying and powder curing, includes sandblasting machine, powder coating guns, powder spray booths, powder coating ovens. COLO, is your one-stop solver for surface finishing.

If you want to buy a powder coating oven, send a inquiry now!

COLO is a leading manufacturer and worldwide supplier of industrial powder coating equipment. With over 10 years design and production experience, our products has been recognized by global clients for its reliable quality, great performance and competitive price. We have professional technical team to customize the size and configurations of powder coating oven based on your workparts. The material preparing, bending, welding, assembling all production process is built in house. With benefits of quick heating, excellent effect and long lifespan, our electric/gas/diesel oven gives you a reliable surface finish.

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize,w_100/quality,q_100)