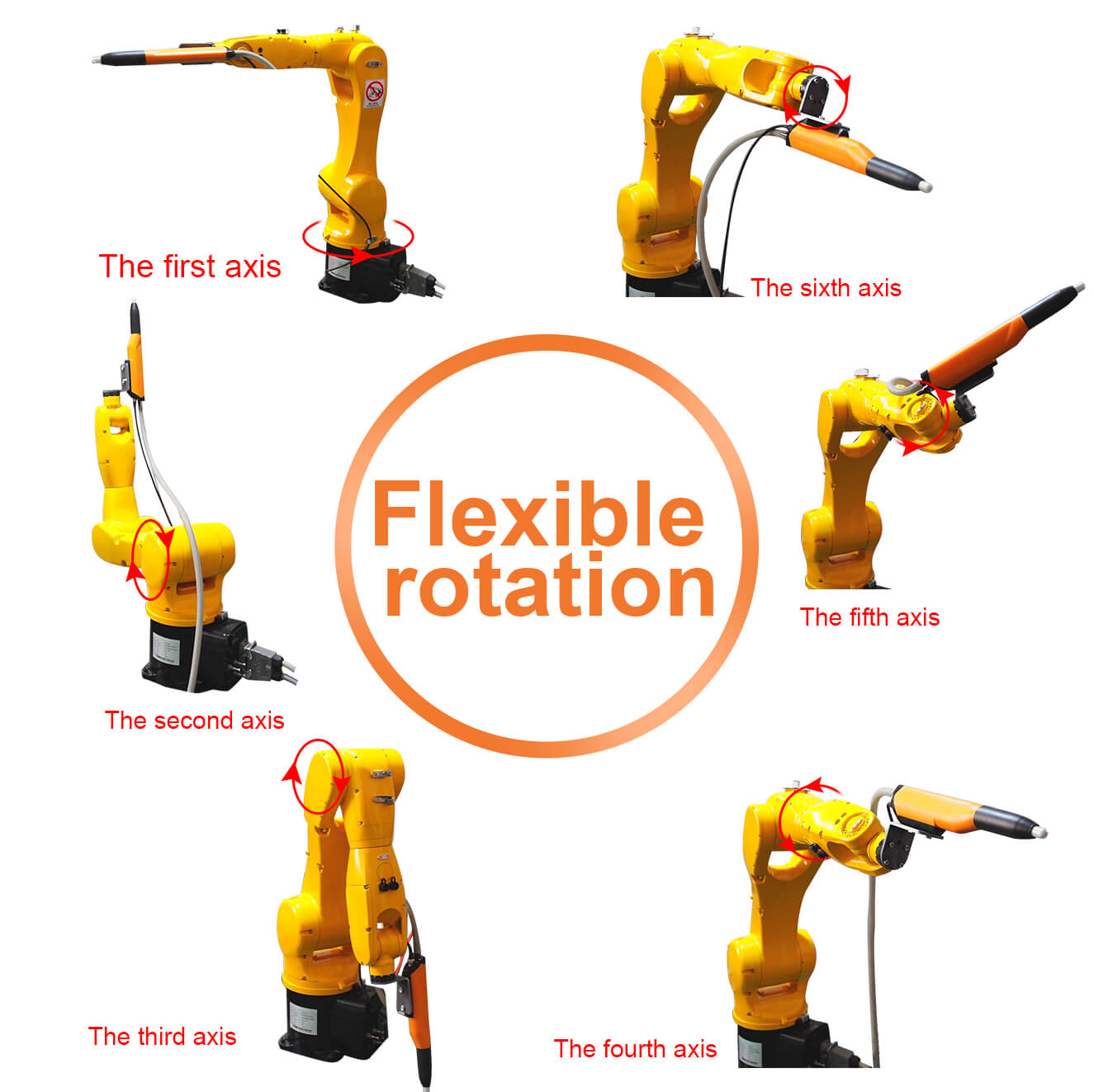

6-Axis Powder Coating & Painting Robot

When maximum flexibility and perfect coating quality are required, robots are the initial choice COLO developed multi-axis robots specially for the coating industry equipped with modern powder application technology. Once programmed, the coating robots efficiently coat parts to the highest quality with magic.

Why choose powder coating & painting robots?

1. Achieve uniform and reproducible coating results,

2. Get more profits through increased efficiency,

3. Optimize the labor cost and material cost.

4. Get easy adjustment and storage of various programs and parameters

5. Improve working conditions

COLO Automatic Spray Guns for Robotic Coating System

Automatic Powder Spray Gun for Robot Coating

Automatic Powder Spray Gun for Robot Coating Automatic Liquid Paint Gun for Robot Coating

Automatic Liquid Paint Gun for Robot Coating

COLO Coating Robot Features

6. Highly flexibille robot can realize spraying on the outer surface and inner surface that saves painting materials.

6-axis Coating Robot Specifications

| Item | Content | Data |

| Specifications | Max. Running Radius | 1500mm |

| Max. Loading | 10kgs | |

| Repeated Posisioning Accuracy | ±0.08mm | |

| Protection Grade | IP67 | |

| Total Weight | 140kgs | |

| Range of Motion | J1 | -180° ~ +180° |

| J2 | -90° ~ +90° | |

| J3 | -75° ~ +255° | |

| J4 | -180° ~ +180° | |

| J5 | -120° ~ +120° | |

| J6 | -360° ~ +360° | |

| Max. Speed | J1 | 150°/s |

| J2 | 150°/s | |

| J3 | 250°/s | |

| J4 | 450°/s | |

| J5 | 650°/s | |

| J6 | 450°/s |

COLO technologies & application devices for coating robots

1. Guns are suitable for plastic and metallic powders based on the latest spraying technology.

2. Robust spraying guns with a large selection of nozzles and are an important key to mastering complex coating requirements.

3. The high transfer efficiency significantly increases the productivity of the system and the low weight is also suitable for

coating robots with a low payload.

6. An interface between the robot control and gun control is necessary to synchronize movement and spraying As the robot movements are performed by a robot control. The coating technology with all its parameters and programs is controlled by a separate gun control unit.

7. Provides various programming methods based on workpiece shape, series size and quality requirements,

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize,w_100/quality,q_100)