COLO-1515 Electric Powder Coating Oven (1.5*1.5*1.5m)

Email: services@colourspray.com

Whatsapp: 8618958052290

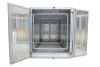

COLO-1515 Electric Powder Coating Oven

Our powder coating ovens are designed specially for powder coating, no pollution for parts and environment. This curing oven uses electricity as heating source to cure pained objects, which features easy-operating and environmental-friendly. There is plenty of space for hanging powder coated metal parts from small to medium size.

Applications: alloy wheels, bike frames, motorcycle parts, metal boxes, metal furniture such as iron chairs, metal shelves, iron art decorative parts, such as lamp holders, etc.

COLO Electric Powder Coating Ovens Features

Rock Wool Insulation Board 100mm

Rock Wool Insulation Board 100mm The powder coating oven insulation material is 100mm thickness rock wool board, which always helps keep the heat in the powder coating oven and out of your work area. The inner wall is 1mm galvanized steel which is heat-resistant, while the outerwall is durable color steel sheet.

Automatic control-simple PLC system

Automatic control-simple PLC system

PLC Control provides high precision heating process, it offers all the features you need. The panel allows you to set the accurate temperature and duration you require, as well as control the working of fan.

Parts Transporting Sysem

Parts Transporting Sysem

COLO powder coating ovens are equipped with 2 trolleys. with inside and outside trolley, it is easy for carry the parts, especially reduce effort for transport heavy workparts. The inner trolley holding parts always stays clean that will not pollutes the oven chamber, keeping the purity of cured parts.

Circulation Fan

Circulation Fan

We can boast a very good temperature uniformity result thanks to the circulation fan, our research has shown that the uniformity of air temperature in the furnace of our circuit does not exceed ±3°C! The fan for small powder coating ovens can be installed on the top to save space.

COLO-1515 Electric Powder Coating Oven Application

Including powder coating gun, powder spray booth and curing oven, this manual powder coating equipment package is an affordable and simple solution for batch processing of alloy wheels. COLO equipment create smooth, uniform and durable finish of wheel surfaces.

COLO-1515 Electric Powder Coating Oven Specifications

| Model | COLO-1515 |

| Inner chamber size: | width1500mm x depth1500mm x height1500mm |

| Outer size: | width1700mm x depth1700mm x height1900mm |

| Voltage: | 220/110V 50/60hz |

| Frequency | 50-60Hz |

| Power supply: | electricity, 18kw |

| Motor power: | 0.55kw |

| Heating time: | 25-30 minutes(180°C) |

| Max. Temperature | 250 °C |

| Temperature stability: | < ± 3-5°C |

| Transportation | Trolley |

Standard Models of COLO Electric Powder Coating Ovens

| Model | Working Dimension(mm) | Heating Power | Fan Motor Power |

| COLO-1515 |

Width1500 Heght*1500 Depth1500 (4.9' x 4.9' x4.9') |

18kw | 0.75kw, 1pcs |

| COLO-1864 |

Width1600 Heght1800 Depth1400 (5.2' x 4.6' x5.9') |

18kw | 0.75kw, 1pcs |

| COLO-1732 |

Width1650 Heght1700 Depth3200 (5.4' x 5.5' x10.5') |

45kw | 1.5kw, 1pcs |

| COLO-1645 |

Width1500 Heght1650 Depth4500 (4.9' x 5.4' x14.7') |

54kw | 3kw, 1pcs |

Why choose COLO powder coating ovens?

We have over 15 years' experience in the design, manufacture, installation, commissioning and ongoing support of the powder coating ovens for industrial use. Our powder coating curing ovens range can be supplied from existing standard sizes or produced to your precise requirements, ranging from electric powder coating ovens, gas/diesel/LPG powder coating, batch or conveyorised ovens. etc. All our curing ovens are built in house from material preparing to electric connection, thus we make them budget-friendly and quality-assured.

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)