-副本.webp?x-oss-process=image/resize,w_100/quality,q_100)

COLO-1732 Electric Powder Coating Batch Oven (1.65*3.2*1.7m)

Email: services@colourspray.com

Whatsapp: 8618958052290

COLO-1732 Big Batch Electric Powder Coating Oven

The 3.2 meter length curing oven is popular among worldwide users, it is designed for drying big bulky parts or a batch production of small-sized parts after powder coating process. Electric heating style reduces the task of operation and maintenance as well as creates a more clean environment.

.webp)

Batch Powder Coating Ovens Trolley System

Our powder coating oven standardly equipped with two carts: internal one and external one, Internal trolley supplied in the form of a frame to loading workparts participating in curing process inside the oven. External trolley is used to carry the internal cart for outside operation and transportation, which will not contaminate the interior of the oven, ensure high purity of painted elements.

It is a superior solution that allows batch loading of workparts as well as carrying heavy elements using a small amount of force.

Our powder coating oven trolley system can be customized to optimize the use of the entire space of the curing oven.

COLO Electric Powder Coating Ovens Configurations

Automatic control-simple PLC system

Automatic control-simple PLC system

PLC Control provides high precision heating process, it offers all the features you need. The panel allows you to set the accurate temperature and duration you require, as well as control the working of fan.

-副本.webp) Rock Wool Insulation Board 100mm

Rock Wool Insulation Board 100mm The powder coating oven insulation material is 100mm thickness rock wool board, which always maintain the warmness in the oven chamber. The inner wall is 1mm galvanized steel which is heat-resistant, while the outerwall is durable color steel sheet.

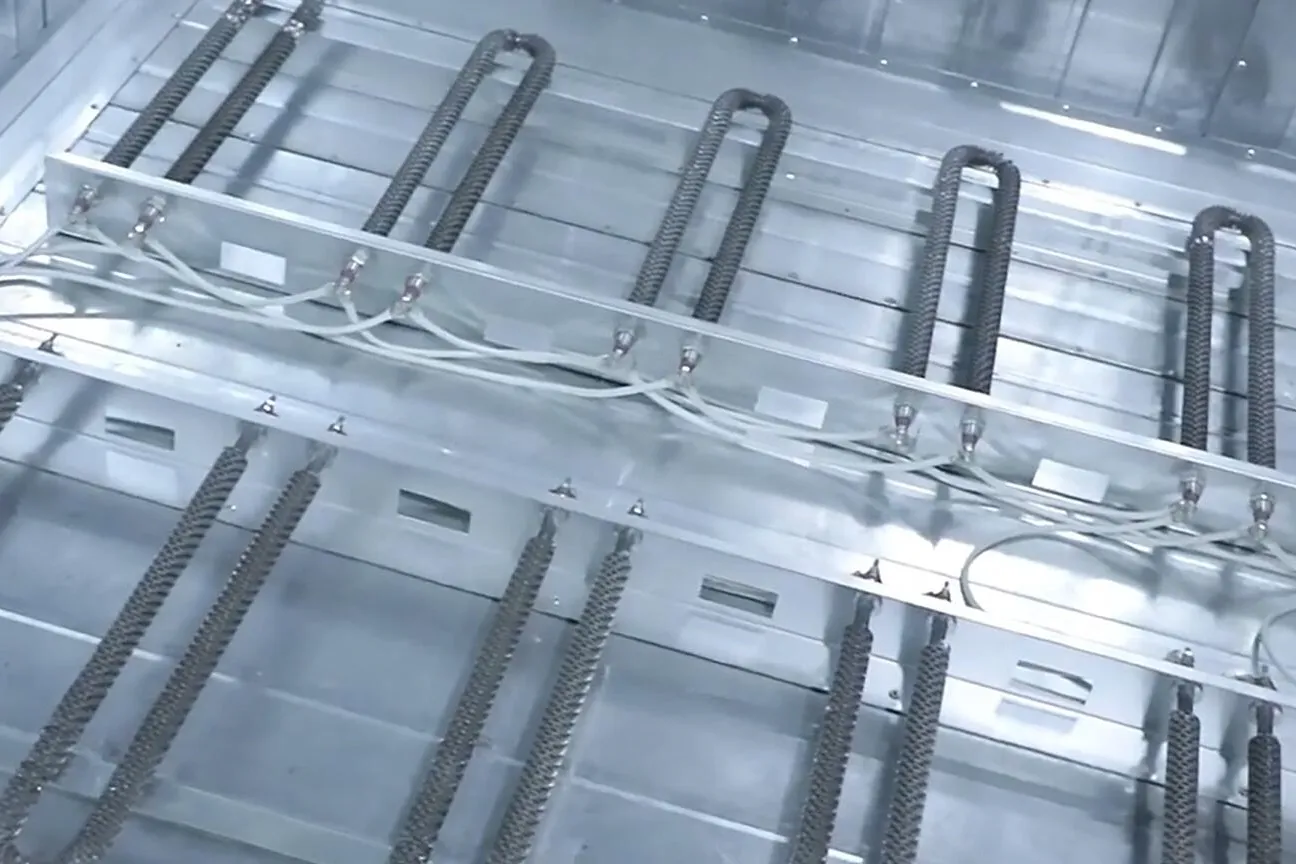

Electric Heating Elements

Electric Heating Elements

Our electric powder coating oven uses 1.5kw U shape heating tubes as heating elements, evenly distributed at the bottom of oven, ensures heating efficiency and uniformity. They are covered with mesh plate, which is easy for maintenance.

Circulation Fan

Circulation Fan

We can boast a very good temperature uniformity result due to the a fan for hot airflow circulation. Our research has shown the temperature stability does not exceed ±3°C. The optimal airflow throughout the powder coating oven enclosure creates an even, constant cure for your parts..

COLO-1732 Electric Powder Coating Oven Specifications

| Model | COLO-1732 |

| Inner chamber size: | width1650 x depth3200 x height1700 (mm) |

| Outer size: | width1950 x depth3500 x height2100 (mm) |

| Voltage: | 220/380V/415V (custom available) |

| Frequency | 50-60Hz |

| Power supply: | electricity, 45kw |

| Motor power: | 1.5kw |

| Heating time: | 25-30 minutes(180°C) |

| Max. Temperature | 250 °C |

| Temperature stability: | < ± 3-5°C |

| Transportation | Trolley |

COLO-1732 Electric Powder Coating Oven Application

COLO-1732 powder coating oven working with COLO-2315 spray booth and COLO-191S powder coating gun, it is a batch powder coating system for medium or big scale production. Their outstanding performance ensures powder application quality and production efficiency.

Why choose COLO powder coating ovens?

We have over 15 years' experience in the design, manufacture, installation, commissioning and ongoing support of the powder coating ovens for industrial use. Our powder coating curing ovens range can be supplied from existing standard sizes or produced to your precise requirements, ranging from electric powder coating ovens, gas/diesel/LPG powder coating, batch or conveyorised ovens. etc. All our curing ovens are built in house from material preparing to welding, assembling to electric connection, thus we make them budget-friendly and quality-assured.

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

-副本.webp?x-oss-process=image/resize)

-副本.webp)