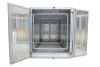

COLO-1118 Powder Paint Curing Oven (1*1*1.8m)

Email: services@colourspray.com

Whatsapp: 8618958052290

COLO-1118 Electric Powder Paint Curing Oven

COLO Industrial powder paint curing ovens feature combination airflow arrangement which provides uniform air distribution along the entire length of the work chamber resulting in quality cured finishes and optimum cure cycles. Our powder coating ovens are available in many standard sizes and custom sizes available on request, the 1x1x1.8m COLO-1118 model is ideal for heat curing small workparts in batches.

COLO Electric Powder Paint Curing Ovens Features

Rock Wool Insulation Board 100mm

Rock Wool Insulation Board 100mm The curing oven utilizes a sandwich panel design. Rockwool insulation of at least 100mm is inserted between galvanized inner wall and color-steel external skins, effectively minimums temperature dropping.

High-precison PLC system

High-precison PLC system

PLC Control provides high precision heating process, it offers all the features you need. The panel allows you to set the accurate temperature and duration you require, as well as control the fan working.

Parts Transporting Sysem

Parts Transporting Sysem

COLO powder coating ovens are equipped with 2 trolleys. which takes full utilization of working space and reduce effort for transport heavy workparts. An external trolley carrying workparts will be pushed into the chamber, an outer trolley transport the internal trollery for loading and unloading, in which cases will not pollutes the oven chamber, keeping the purity of cured parts.

Circulation Fan

Circulation Fan

We can boast a very good temperature uniformity result thanks to the circulation fan, our research has shown that the uniformity of air temperature in the furnace of our circuit does not exceed ±3°C! The fan for small powder coating ovens can be installed on the top to save space.

COLO-1118 Electric Powder Paint Curing Oven Specifications

| Model | COLO-1118 |

| Inner chamber size: | width1000mm x depth1000mm x height1800mm |

| Voltage: | 220/110V 50/60hz |

| Frequency | 50-60Hz |

| Power supply: | electricity, 15kw |

| Motor power: | 0.55kw |

| Heating time: | 25-30 minutes(180°C) |

| Max. Temperature | 250 °C |

| Temperature stability: | < ± 3-5°C |

| Transportation | Trolley |

Standard Models of COLO Electric Powder Coating Ovens

| Model | Working Dimension(mm) | Heating Power | Fan Motor Power |

| COLO-1515 |

Width1500 Heght*1500 Depth1500 (4.9' x 4.9' x4.9') |

18kw | 0.75kw, 1pcs |

| COLO-1864 |

Width1600 Heght1800 Depth1400 (5.2' x 4.6' x5.9') |

18kw | 0.75kw, 1pcs |

| COLO-1732 |

Width1650 Heght1700 Depth3200 (5.4' x 5.5' x10.5') |

45kw | 1.5kw, 1pcs |

| COLO-1645 |

Width1500 Heght1650 Depth4500 (4.9' x 5.4' x14.7') |

54kw | 3kw, 1pcs |

Why choose COLO powder coating ovens?

We have over 10 years' experience in the design, manufacture, installation, commissioning and ongoing support of the powder coating ovens for industrial use. Our powder coating curing ovens range can be supplied from existing standard sizes or produced to your precise requirements, ranging from electric powder coating ovens, gas/diesel/LPG powder coating, batch or conveyorised ovens. etc. All our curing ovens are built in house from material preparing to electric connection, thus we make them budget-friendly and quality-assured.

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)