COLO-1115 Small Powder Coating Spray Booth

This small powder coating spray booth is an economical solution for basic powder coating operations requiring reclaim capability in continuous production situations. For small powder coating job shops, first-time powder coaters this small powder spray booths offers high performance, reduce efforts and save budget.

COLO Small Powder Spray Booth Benefits

1. Built with durable, long-life powder-coated steel, designed with a compact structure

2.Low-profile booth base eliminates operator's fatigue for powder coating jobs.

3. Twopieces quick-release type filter for powder recovery, convenient for cleaning and color change.

4.1.5kw fan motor installed on the top to save space, powerfulextraction capacity with low noise

5. Automatic filter cleaning controlled by pulse-jet, which prevents powder accumulation and extends filter life.

6.Requires only quick, easy electrical and pneumatic connect to start production.

![powder coating booth control unit]()

Control Unit

Powder Collector

Cartridge Filters

Fan Motor

Small Powder Spray Booth Specifications

| Model | COLO-S-1115 |

| Booth Type | Closed |

| Operator dimensions | 1000width x 1500 height x 1000 depth (mm) |

| Overall dimensions | 1200width x 2000 height x 1500 depth (mm) |

| Weight | 200kg |

| Power supply | Electric |

| Nominal power | 1.5kW |

| Voltage | 380V |

| Frequency | 50-60Hz |

| Filters | Polyester, D325xH600mm |

| Filters count | 2 |

| Filters hang type | easy for change |

| Filter cleaning system | Pneumatic |

| Warranty | 12 months |

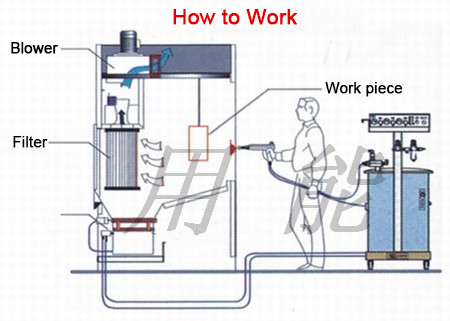

How Powder Coating Booth Works

Our Powder Coating Booths make efficient use of shop space and are designed for simple manual application with overspray reclamation. During powder spraying process, shop air is drawn into the spray booth by a fan blower, it passes through the booth's workspace at the same time carrying the oversprayed powders. The powder particulates suspended in the air flow will stick onto a cartridge filter stage integrated in the booth wall. Thus the air is filtered that is free of particulates and then discharged back into the workshop. The powders stick in the filters will be released via pulse jet devices controlled by PLC.

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)