.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Manual Powder Coating System with Light Customization

Email: services@colourspray.com

Whatsapp: 8618958052290

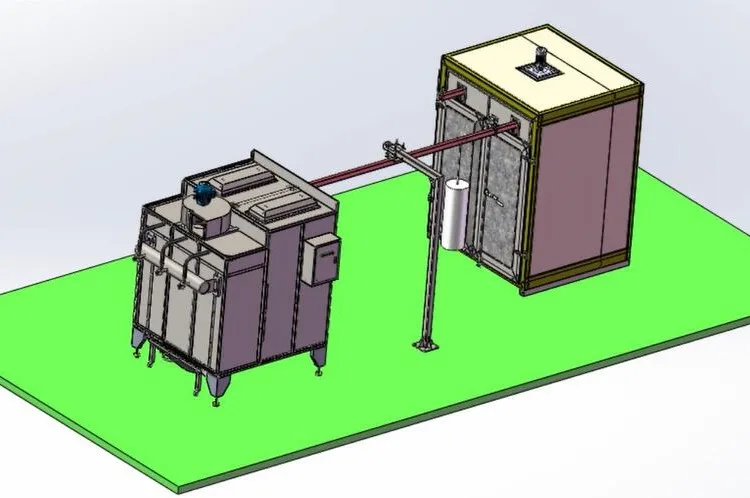

Manual Powder Coating System with Light Customizations

The manual powder coating system consists of COLO standard equipment and integrates light customizations. The users firstly performs powder spraying at spray booth, afterwards, the coated parts with be pulled into the curing oven through a U-shape overhead track connecting booth and passing through the oven.

This powder coating solution suits for small to medium dimensional workparts, It reduces labor efforts, increase efficiency while requires less space and budget.

Including COLO-191S powder coating gun, COLO-1517 spray booth and COLO-1864 curing oven, this professional powder coating system meets the high requirement of using experience: easy applying of powders onto most complex worparts, a dustless working environment, effective overspray recovery, and consistent cure quality. COLO system saves your powder, saves your time and improve results.

Manual Powder Coating System Main Configuration

COLO-191S Powder Coating Machine

COLO-191S offers precise and efficient operations with digital valve gun control and 100kv powerful spray gun, leads to superior quality surface finish with saving time and materials.

.webp)

Excellent Features

1. Dgital Valve Controlled Technology Offers Precise & Flexible Control of all parameters, suits hard and challenging jobs,

2. Offers 3 pre-set standard application programs for flat parts, profiles and re-coating .It is very simple to operate for a beginners. Allows users create 20 customized programs optimized for their parts and powders.

3. The powerful manual spray gun is built with 100kv cascale for high transfer efficiency.

4. Supplied with full assembly of nozzles to help handing different shapes, including round nozzles, flat nozzles, extension nozzles

5. Available for 60lbs hopper type and fast color change box feed type.

| Specifications | |

| Power Range | 220V/110V |

| Frequency | 50HZ/60HZ |

| Temperature range in use | -10 ℃+50 ℃ |

| Gun Weight | 500G |

| Rated output voltage | 24VDC |

| Input Voltage | - 200kv |

| Maximum output current | 180Ua(max) |

| Maximum output voltage | 0-100KV (adjustable) |

| Maximum powder injection | 600g/min |

| Polarity | negative (-) |

COLO-1517 Powder Coating Booth

The COLO-1517 powder booth is convenient to use with manual powder coating machine and curing oven, suitable for batch production of small to medium sized parts. Based on COLO technology, It is an universal and economic powder recovery system.

Manual Powder Coating Booth Features

1. Comes with 3 pcs of cartridge filters and 2.2kw extraction fan powerfully capture oversprayed powders, reach to 98% powder recycle rate

2. Automatic pulse filter cleaning prevents programmed via PLC prevents the accumulation of the powder and extend filter's life.

3. Quick-release type cartridge filters are designed for quick color change demands.

4. Durable Powder-coated steel structure ensure long service life.

5. Overhead lighting and rail systems makes the powder coating job easier and better.

| Specifications | |

| Operation Dimension | Width1500 * Depth1500 * Height1700 (mm) |

| Overall Dimension | Width1600 * Depth2000 * Height2250 (mm) |

| Power Supply | AC 380V (can be customized) |

| Frequency | 50-60 HZ |

| Power Consumption | 2.2KW |

| Air Comsumption | 40003m3/h |

| Filters | Polyester |

| Filter Count | 3(325*900mm) |

| Filter Cleaning System | pneumatic |

| Machine Weight | 400kg |

| Warranty | 12 months |

COLO-1864 Electric Powder Coating Oven

Our curing ovens are designed specially for powder coating, When a thermoset powder is exposed to required temperature, it begins to melt, flows out, and then chemically reacts to form a higher molecular weight polymer in a network-like structure.

1. Electric heating source powder coating oven, environmetal friendly and easy operated

2. Rapidly raise to the required temperature, save your time every day.

3. Uniform heat distribution in inner chamber thanks to circulation fan and optimal airflow.

4. 100mm thickness rock wool board of the interlayer, keep long time heat preservation.

5. PLC panel controls the working of fan, sets the time and temperature, provides a precise and reliable heating process.

| Specifications | |

| Worksize dimensions(mm) | Width1600 x Height1800 x Depth1400 (mm) |

| Overall dimensions(mm) | Width1900 x Height2200 x Depth1700 (mm) |

| Power supply | Electric/ 12kw |

| Voltage/Frequency | 380V/220v(50-60hz) |

| Warm-up time | 15-30 min. (180° C) |

| Temperature stability | < ± 3-5°C |

| Temperature max. | 250° C |

| Ventilation performance | 805-1677m3/h |

| Motor power | 0.75kw |

| Circulation/ Air flow | Vertical ,Variable through holes on the walls |

| Transportation | Trolley |

| Warranty | 12 months |

Size and special requirements can be customized based on actual powder coating products.

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

-副本.webp)

.webp?x-oss-process=image/resize,w_100/quality,q_100)