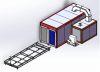

COLO-5219 Gas Powder Coating Curing Oven (1.9*5*1.9m)

Email: services@colourspray.com

Whatsapp: 8618958052290

COLO-5219 Gas Powder Coating Curing Oven

This 5 meter powder coating oven has enough space to hold big batches of workparts, which is recommended to use natural gas, LPG or diesel as heating source that quickly gets to required temperature. Fully burning of fuels, our curing oven increases powder coating efficiency and saves energy expense.

COLO curing ovens are standardly equipped with loading frame and transportation trolley, which saves your efforts to operate especially for heavy workparts. Trolleys can be designed accoriding to your workparts as well as maximize the utilization of oven space.

Gas Powder Coating Curing Oven Components

Forced air

Forced air Our curing oven can boast a very good temperature uniformity result through a circulation fan, our research has shown that the uniformity of air temperature in the furnace of our circuit does not exceed ±3°C! The result is due to our technology of horizontal, and vertical air circulation, the circulation is chosen according to the process.

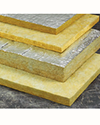

Thick insulation 100-150mm

Thick insulation 100-150mmOur walls are built with 1.5mm panels filled with 100-150mm thickness rock wool insulation, which helps keep the heat in the powder coating oven and out of your work area. .

Easy-to-Use PLC Control

Easy-to-Use PLC ControlControl provides high precision heating process, it offers all the features you need. The LED display allows you to set the temperature, as well as the duration of heating process at the desired temperature.

RIELLO Burner

RIELLO BurnerExport into worldwide Italy imported burner. The high performance burner takes full utilization of burning fuels, energy-saving.

COLO-5219 Gas Powder Coating Curing Oven Specifications

| Worksize dimensions | 1900 width x 1900 height x 5000 depth mm |

| Overall dimensions | 2100 width x 2480 height x 5200 depth mm |

| Power supply | Gas/LPG/Diesel |

| Voltage/Frequency | 380V/220v(50-60hz) |

| Warm-up time | 15-30 min. (180° C) |

| Temperature stability | < ± 3-6°C |

| Temperature max. | 250° C |

| Ventilation performance | 8288-16576m3/h |

| Motor power | 5.5kw |

| Circulation/ Air flow | Two stage fire, Italy Riello, 20,0000kcal |

| Transportation | two Trolleys |

| Warranty |

12 months |

We supply standard modes of powder coating oven with lower cost, also provide custom services, oven sizes and configurations can be designed as your precise requirements.

Why choose COLO powder coating ovens?

1. Our powder coating ovens are designed specially for powder coating, no pollution for parts and environment.

2. We use advanced heating technology that gets the air to temperature faster – which saves you times every day. It uses less fuel, which saves on your operating costs.

3. Our walls are built panels filled with 100mm mineral wool insulation, which helps keep the heat in the powder coating oven and out of your work area.

4. The entire design is built to create optimal airflow throughout the powder coating oven enclosure, preventing hot spots and providing an even, constant cure for your parts.

5. We offere custom designs and sizes of powder coating ovens as you required.

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)