Batch Powder Coating Oven with Overhead Rails

Email: services@colourspray.com

Whatsapp: 8618958052290

Batch Powder Coating Oven with Overhead Rails

For this kind of powder coating ovens, overhead trolley rail system is designed in order to carry material into the oven manually, especially it is suitable for the heavy and bulky part.

With double-opened doors, this oven allows to cure parts continuously by loading them from one side and removing coated ones from another.

The rail type powder coating oven can be heated by electric, gas or diesel as required, the quantity of to tracks can be also customized.

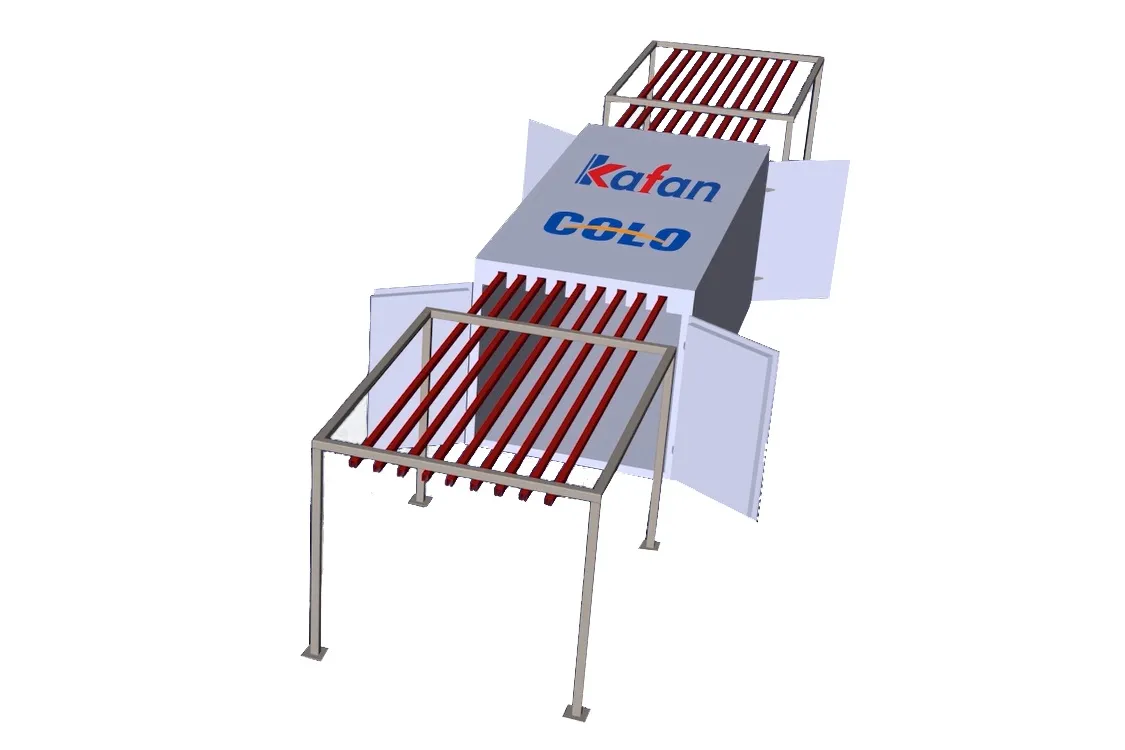

Overhead Rail Powder Coating Oven

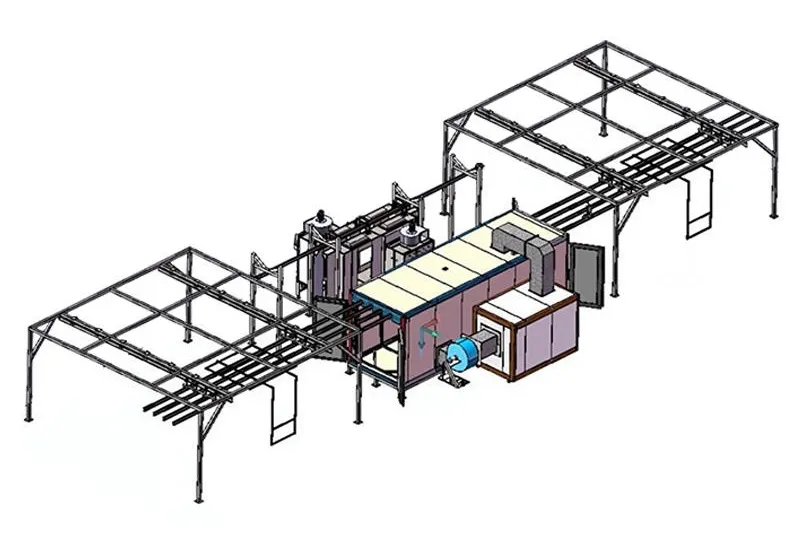

Overhead Rail Powder Coating Oven Overhead Rail Powder Coating Plant

Overhead Rail Powder Coating Plant

Overhead Rail Powder Coating Oven Applications

In the bach powder coating plant, powder coating oven with rails are suitable for big and heavy materials, such as aluminium profiles, long plates, bulky frames or large quantity small items.

Our powder coating ovens are made of high quality materials and superior performance componenets, ensures efficient heating circles and durable, unform curing results.

7m Overhead Rail Powder Coating Oven Specifications

| Worksize dimensions | 1800 width x 2100 height x 7000 depth mm |

| Overall dimensions | 2000 width x 2400 height x 7200 depth mm |

| Power supply | LPG/Diesel/Gas |

| Voltage/Frequency | 380V/220v(50-60hz) |

| Warm-up time | 15-30 min. (180° C) |

| Temperature stability | < ± 3-6°C |

| Temperature max. | 250° C |

| Ventilation performance | 8288-16576m3/h |

| Motor power | 5.5kw |

| Bruner | Italy Riello, 20,0000kcal |

| Transportation | Overhead Conveyor |

Overhead Rail Powder Coating Oven Details

Circulation Fan

Circulation FanWe use 5.5kw high performance circulation fan which provides uniform air distribution along the entire length of the work chamber resulting in quality cured finishes and optimum cure cycles. The fan motor is specially made to prevents high temperature which is safer and longer life.

RIELLO Burner

RIELLO Burner

Italy imported RIELLO burner. The high performance burner takes full utilization of burning fuels, giving quick raise of high temperature, tme-saving, energy-saving.

PLC Control System

PLC Control System

Control provides high precision heating process, it offers all the features you need. The LED display allows you to set the temperature, as well as the duration of heating process at the desired temperature.

100mm Thick Rockwool Board

100mm Thick Rockwool Board

The powder coating oven insulation material is 100mm thickness rock wool board, which always helps keep the heat in the powder coating oven and out of your work area. The inner wall is 1mm galvanized steel which is heat-resistant, while the outerwall is durable color steel sheet.

Why choose COLO powder coating ovens?

1. We have 16 years in designing and manufacturing curing ovens specially for powder coating, no pollution for parts and environment.

2. We use advanced heating technology that gets the air to temperature faster – which saves you times every day. It uses less fuel, which saves on your operating costs.

3. Our walls are built panels filled with 100mm mineral wool insulation, which helps keep the heat in the powder coating oven and out of your work area.

4. The entire design is built to create optimal airflow throughout the powder coating oven enclosure, preventing hot spots and providing an even, constant cure for your parts.

5. We offere custom designs and sizes of powder coating ovens as you required.

Contact us for price of the 7m oven, or design a powder coating oven specially for you!

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp)