COLO-0813 LPG/Gas Powder Coating Oven (0.8*3*1.5m)

Email: services@colourspray.com

Whatsapp: 8618958052290

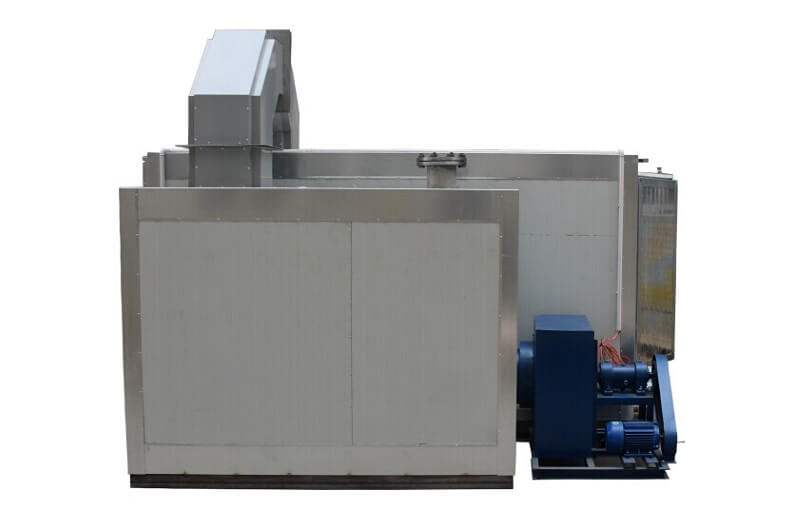

COLO-0813 LPG/GAS Powder Coating Curing Oven

Gas/LPG powder coating curing oven is designed for saving energy expense by replacing of electric oven, and it is more durable and has longer lifespan. COLO gas powder coating oven features quick rising of temperature and uniform heat distribution, ensures effective and perfect curing quality. By using 100mm thickness rock wool board, the gas oven ideally preserves the required heat, making temperature stability less than 3 degree.

How LPG/gas powder coating oven works?

The majority of the air is recirculated through the heat system, while a small amount of air is exhausted to the outside atmosphere to meet code requirements. For the indirect-fired heat system,the Italy Riello brand burner is fired into a Radiant Tube type heat exchanger, filter many of the combustible and toxic fumes produced with the heated air. then make the curing part clean. and high CFM recycling fan assure rapid temperature rise and consistent curing temperatures. This powder coating oven includes PLC controls to predict and adjust heat system performance.

LPG/Gas Powder Coating Oven Configurations

Air Circulation Fan

Air Circulation FanForced air circulation and floor, we can boast a very good temperature uniformity result, our research has shown that the uniformity of air temperature in the furnace of our circuit does not exceed ±3°C! The result is due to our technology of horizontal, and vertical air circulation, the circulation is chosen according to the process.

100mm Insulation Wall

100mm Insulation WallOur ovens are built with with 1mm heat-resistent galvanized innerwall and durable steel outerwall, filled with 100mm thickness rock wool insulation, which keeps the heat in the powder coating oven and out of your work area. .

Simple PLC Control

Simple PLC ControlControl provides high precision heating process, it offers all the features you need. The panel allows you to set the temperature, as well as the duration of heating process at the desired temperature.

RIELLO Burner

RIELLO BurnerItaly imported RIELLO burner. The high performance burner takes full utilization of burning fuels, energy-saving. Less time is needed to reach the required curing temperature.

COLO-0813 LPG/GAS Powder Coating Oven Specifications

| Worksize dimensions | Width800*Heght*1500*Depth3000mm |

| Overall Dimension | Width1200*Heght*1400*Depth3500mm |

| Power supply | Gas/LPG |

| Voltage/Frequency | 380V/220v(50-60hz) |

| Warm-up time | 15-30 min. (180° C) |

| Temperature stability | < ± 3-5°C |

| Temperature max. | 250° C |

| Ventilation Performance | 1131-25657m3/h |

| Burner | Italy Riello, 100,000cal |

| Motor power | 1.5kw |

| Circulation/ Air flow | Vertical ,Variable through holes on the walls |

| Transportation | Trolley |

| Warranty | 12 months |

A variety of standard models for choice, custom size and design also available

| Model | Working Dimension | Buner Power | Fan Motor Power |

| COLO-0813 | Width800 * Heght1500 * Depth3000mm | 100,000kcal | 3kw, 1pc |

| COLO-1732 | Width1650 * Heght1700 * Depth3200mm | 100,000kcal | 4kw, 1pc |

| COLO-3210 | Width2000 *Heght1900 * Depth3100mm | 100,000kcal | 4kw, 1pc |

| COLO-5219 | Width1900 * Heght1900 * Depth5000mm | 200,000kcal | 5.5kw, 1pc |

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)