-副本.webp?x-oss-process=image/resize,w_100/quality,q_100)

COLO-6600 Powder Management Center for Automatic Powder Coating Application

Email: services@colourspray.com

Whatsapp: 8618958052290

COLO-6600 Powder Management Center for Automatic Powder Coating Application

The newly-developed powder management center is an integrated solution in automatic powder coating line for continuous powder feeding, efficient powder sieving, automatic cleaning during color change

with the following highlights:

- Designed with a big capacity powder container ensures continuous powder feeding for automatic spraying

- Automatic cleaning of powder injectors, pumps, hoses and spray guns, suction tube, maximize efficiency during color change.

- Closed powder circuit prevents overflow to ensures a clean, dustless working environment as well as save powders.

- Has a very compact design and can be flexibly adapted to any system layout.

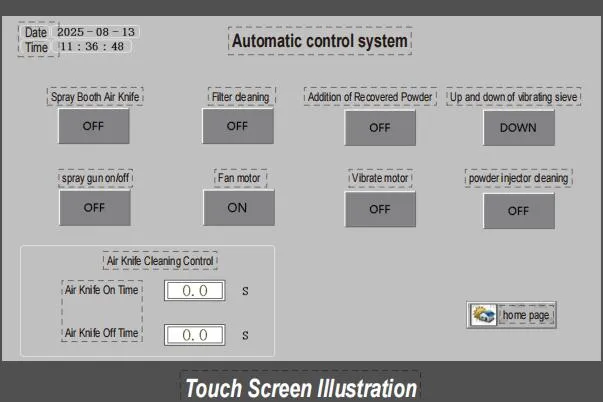

PLC System with Touch Control

- PLC system with touch screen is particularly intuitive that integrates all functions you need.

- Control every component of powder coating line, such as powder feeding, powder recovery, powder booth cleaning, reciprocating, fan working and curing time, etc

- Extremely easier operation of the coating and color change process

Vibrate Sieving Unit:

- Connect with booth recovery system for automatic sieving of recycled powders, ensure purity.

- Dissolving and loosening of powder accumulations for even powder flow.

- Provide gentle sieving and require less energy.

- Can be set for automatic lifting or descending for easy operation

.webp)

Powder Hopper

- Allows containing high volume of powders for countinuous production without frequnty interruption

- With optimal fluidization condition for smooth powder flow and quality coating results

- Can be flexibly removed out for easy cleaning during color change operation.

- With detection of the powder level that shows at display, guarantee a constantly available powder quantity.

- Closed powder hopper avoids powder escaping and ensure clean working environment,

-副本.webp)

COLO-6600 Powder Management Center Specifications

| Power supply : | AC 220V/110V 50Hz-60Hz (as required) |

| Overall size |

width1350 * height1940 * depth900(mm)

|

| Powder hopper size: | 550*550*550mm |

| Sieve frame size: | φ400mm |

| Standard mesh size: | 80 mesh (on request) |

| Required air pressure | 6-8bar |

| Air consumption | About 300 m³/h standard |

| Recommended Air Compressor HP | 20kw(30HP) |

| Ambient: | 5-40 ℃ |

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

-副本.webp?x-oss-process=image/resize)