.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Automatic Reciprocating Powder Coating Machine

Email: services@colourspray.com

Whatsapp: 8618958052290

Automatic Reciprocating Powder Coating Machines

The automatic reciprocating system includes COLO-191S series automatic coating guns, COLO-2400D PLC reciprocator, A central control cabinet combines a certain quantity of powder gun controllers, ensures reliability and controllability. combined with reciprocator system. achieves constant, quality and effective application.

It is the best choice for high production powder coating line delivering superior finish quality and great powder savings.

COLO Automatic Powder Coating System Application Cases

COLO has designed, manufacturered, exported and built a lot of powder coating plants projects in worldwide.

- COLO-191S Powder Coating System for Auto Parts

- COLO-191S Powder Coating System for Aluminium Profiles

COLO-191S Automatic Powder Coating Machine

Precise Control Unit

Developed by COLO experts delivers superior-quality finish and very significant powder savings which has been proved by worldwide users.

The applied digital valve control technology allows precise adjustment of powder output, which helps users always find the right powder amount to objects, improve the film thickness consistency.

Flexibly control all the electrostatic and pneumatic parameters is a great importance to ideally coat challenging powders or shapes.

Offers beginners 3 pre-set application programs for most jobs Flat-parts, Complicated parts, Re-coating: Allows experienced users to create and store customized 20 application programs, optimized for their parts and powder.

Integrated Central Cabinet

All controller units are integrated on a central cabinet, a host unit controls all the units, which means you just need set parameters in one master controller featuring easy to train and operation. The quantity of the conrtoller units installed is taileroed based on the actual applications.

Technical Parameters

| Power Input | AC 220V±10%,50Hz,160 ~320W |

| HV Output | 0~100KV Stepless Adjustable 0~60μA Stepless Controllable |

| Air Input | 0.4~0.8 MPa |

| Max. Air Consumption | 4×13Nm3/h—8×13Nm3/h |

| Powder Output(for each gun) | 0~ 500g/min |

| Max. Oil and Water Contents in Compressed Air | Oil:0.1mg/Nm3 Water:1.3g/Nm3 |

| Safety Standard | IP54 |

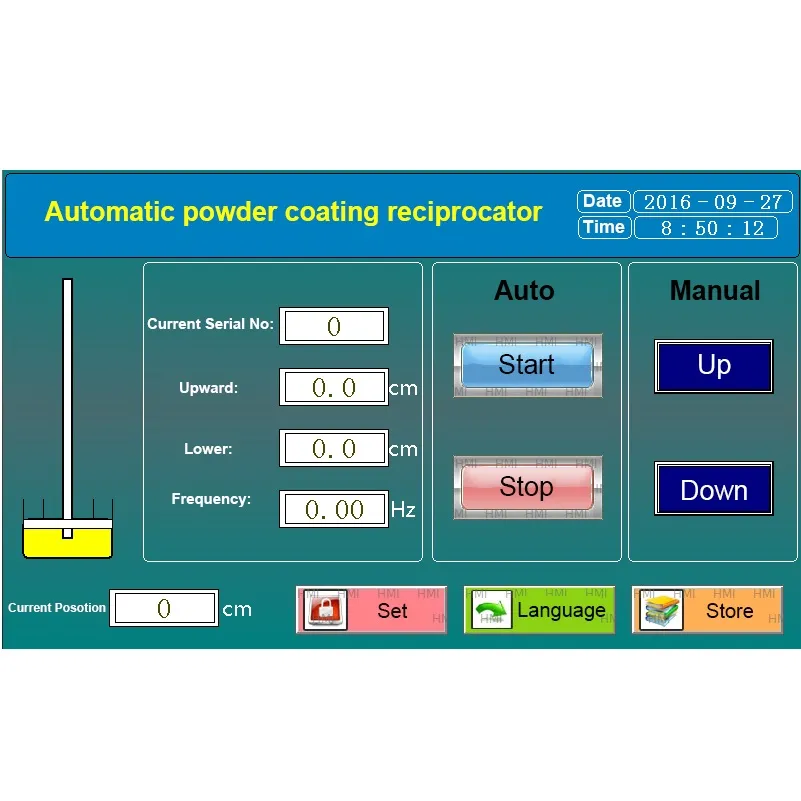

COLO-2400D PLC Controlled Powder Coating Reciprocator

Excellent Features

1.COLO Reciprocator is designed for consistent and uniform coating in automatic production line with great powder savings.

2. Driven through a frequency adjustable motor controlled via PLC, whose speed and stroke can be accurately set on the touching screen,

3. Spraying guns' movement is programmed in various speeds & strokes to suit conveyor speed & object height respectively. Jobs are storable with 20 programs, and easily selected from the controller.

4.The heavy-duty reciprocator allows to install up to 12pcs automatic spray guns with high stability. Sturdy construction could adapt to continual load everyday operational conditions.

The spray gun arrangement can be horizontal or vertical, the quanity is customized, all depend on the object shape, required output, etc.

Technical Parameters

| Model | COLO-2400D |

| Rated voltage | AC220V~240V/50~60Hz |

| Rated power | 0.75Kw |

| Speed | 0.08m/S-0.8m/S (adjustable) |

| Stroke | 1.5m 1.8m 2m 2.5m |

| Setting system | PLC with touch screen |

| Speed control method | frequency conversion |

| Required temperature | -10~50℃ |

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg)

.webp)