Automatic Powder Coating Booth System for Fast Color Change

Email: services@colourspray.com

Whatsapp: 8618958052290

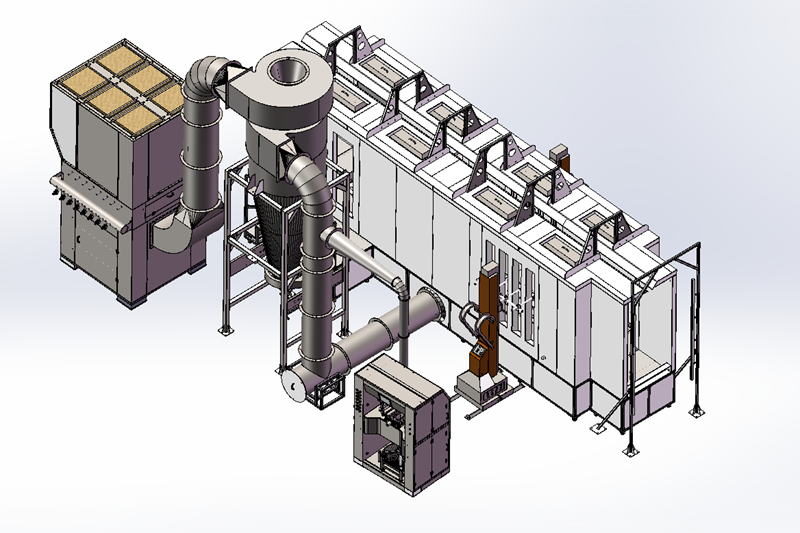

Automatic Cyclone Powder Coating Booth and Spraying System

The High Productivity Automtic Powder Coating System includes pp plastic spray booth with mono cyclone, reciprocators, automatic coating guns & equipment, integrated powder management center, it is the most efficient solution for powder recovery, quick color change demands and a dustless working environment.

Automatic Powder Coating Booth System Application

COLO has built a lot of powder coating plant all over the world, and the applications range from small auto parts, metal accessories to big furniture products and long aluminium profiles. Our automatic powder coating equipment are proved that delivers outstanding performance

Automatic Cyclone Powder Coating Booth

PP plastic made powder coating booth with cyclone recovery is the most efficient solution for fast color change or high powder recovery demands in automatic powder spraying line.

Non-conductive plastic booth wall, self-cleaning booth floor, matching with the mono-cyclone separator and after filter unit recovey system, make the spray booth creates least powder accumulation and the most environmental-friendly emission.

Excellent Features

PP Plastic Wall(an-static material)

PP Plastic Wall(an-static material)The booth wall is made of anti-static PP plastic materials, which is non-stick of powders and easy for cleaning. It maximizes recovery efficiency, reduces downtime during fast color change.

High cleaning and recovery efficiency contributes to a clean, safe coating environment. Ensure the highest color change quality in as short as 15-30 minutes, ensuring confident and consistent production.

Self-cleaning Booth Floor

Self-cleaning Booth FloorThe automatic powder coating booth floor is specially for self-cleaning, which continuously transports oversprayed powder safely and quickly to the powder recycling system.

The cleaning system is controlled by air blasts, which remove the powder accumulated on the booth floor and push it to the extraction and recovery system. The booth floor remains clean, with just a minimum amount of powder.

Cyclone Recovery System

Cyclone Recovery SystemThe mono-cyclone is made of durable coated steel, During powder spraying procedures, overspray powder flow will be transfered to cyclone first.

The cyclone equipment uses centrifugal force and gravity to separate particulates according to their relative density. Thus, the powders will be effectively separated from the air stream. The cyclone is one of the important part in high volume powder coating jobs

As there are also some ultrafine powder particulates with light gravity will not fall down to cyclone bottom, they will be transfered to filter cartridges for final collecting, thus evented air stream from the whole system is free of dust particulates, creating a clean working environment.

Secondary filter recovery unit usually includes 9-16pcs cartridge filters cleaning by automatic pulse jet devices.

Automatic Cyclone Powder Coating Booth Specifications

| Model | COLO-S-PP |

| Booth Type | Automatic Type |

| Operator dimensions | Width800 x Depth6000 x Height2000 mm |

| Weight | 4000kg |

| Power supply | Electric |

| Nominal power | 15kw |

| Voltage | 380V/220V. customized as local. |

| Frequency | 50-60Hz |

| Filters | Polyester |

| Filters count | 32pcs (325*900) |

| Filters hang type | Rotary Wing, help filter cleaning |

| Filter cleaning system | Pneumatic |

| Warranty | 12 months |

Automatic Powder Coating Guns & Equipment

The COLO-191S Automatic Guns & Central Cabinet, COLO-2200D PLC Reciprocator, COLO-6600 Powder Feed Center are the highest standard for automatic powder coating line, the combination moves to a new level of powder coating efficiency

The automatic coating system delivers typically excellent finishes with consistent uniform film thickness even in high speed conveyorised powder coating lines, and greatly saves your powders that minimize production cost.

Excellent Features

Powder Coating Reciprocator

Powder Coating Reciprocator

1) Smooth and gentle movement through belt increases uniformity of powder coating flim thickness.

2) Jitter-free operation causes lower noise and less wear-resistance.3) Can carry up to 24 pcs automatic powder spray guns for reliable and stable running.

4) Allows create and store 20 kinds of pre-programmable settings for automatic selection of stroke and speed.

5) User-friendly PLC system with touch screen controls speed and stroke length accurately.

Automatic Guns & Central Control Cabinet

Automatic Guns & Central Control Cabinet1) A central control cabinet combines a certain quantity of automatic powder gun controllers for integrated operation.

2) Meet the requirements of serial production in powder coating line, ensures reliability and controllability.

3) All units are integrated to be controlled in one master controller, which is easy to train and operation.4) The quantity of the powder coating units installed in the cabinet can be custom based on the actual applications.

COLO-191S Intelligent Gun Control

COLO-191S Intelligent Gun Control1) 0-100kv voltage adjustable, suitable for any shape of parts, perfect for challenging areas.

2) Flexibly adjust kv, amperage, automizing air, feeding air by buttons, values showed in LCD digital display.

3) Three pre-set coating modes support for panels, corners and re-coating, as well as allows to store 20 personalized programs.

4) Basic, startup automation tools for industrial powder coating set up, reaches new lever of productivity.

.webp?x-oss-process=image/resize) Powder Management Center

Powder Management Center1) Integrated solution for powder feeding, powder sieving, powder recycling in automatic coating line,

2) Allows directly placing the original powder package into the bottom funnel, much more flexible for color change.

3) Automatic cleaning of hopper, suction tube, injectors, pump, hoses and spray guns, maximize efficiency during color change.

4) Closed powder circuit prevents overflow to ensures a clean working environment as well as save powders.

5) Has a very compact design and can be flexibly adapted to any system layout.

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

-副本.webp?x-oss-process=image/resize,w_100/quality,q_100)