Custom-built Manual Powder Coating Plant in Saudi Arabia

Dec 01, 2022

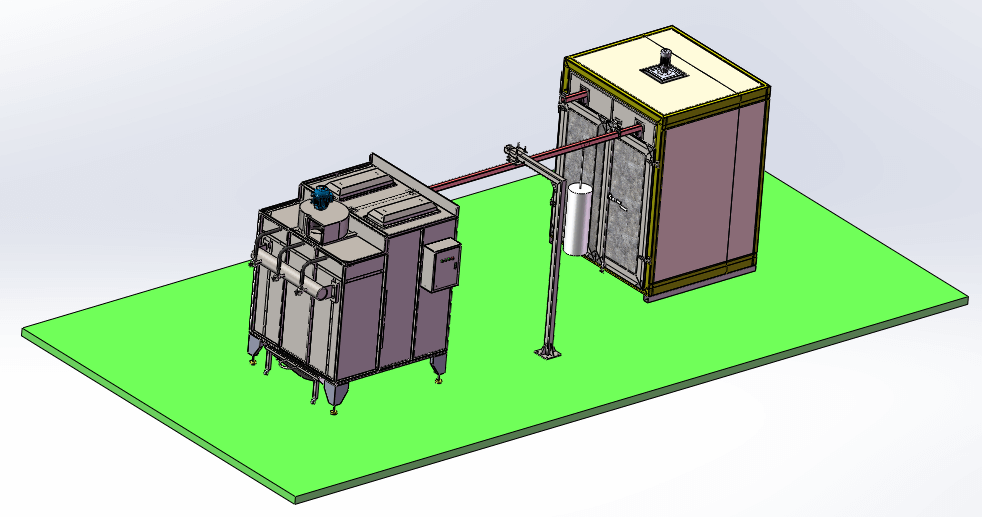

The powder coating plant based on manual operation, is designed for our Saudi Arabia customer for their fire hydrants application. Though it is an easy and budget-saving plant, they got sufficient productivity and extraordinary surface coating quality

The key point is the special technology that the customer requires using the oven to heat the fire hydrants first, then immediately spraying with powder coating, the specially powder material will melt and cure itself on the scalding surface. In such case, the being coated workparts should maintain a certain high temperature.

Thus we recommended a U-shape top rail connecting powder booth and curing oven. When a batch of fire hydrants get heated, manually moves one piece out of the curing oven across the rail to the spray booth, the rest ones will be left inside the oven to keep the heat.

The shape of the fire hydrants looks not big but kinds of complicated, so we recommend our star model COLO-191S manual powder coating system, which is professional to coat any shape of metal objects, even with deep corners, holes. The accuracy of adjusting parameters, such as kv, amperage, powder output, atomization offers operation great flexbility to handing any different jobs. According to the customer's not big scale production, we recommended the COLO-1517 powder coating booth (1000x1500x1700mm) and COLO-1864 powder coating oven (1600x1400x1800mm).

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Jun 17, 2025

Feedback of COLO Powder Coating Line in Australia

Oct 17, 2023

Visit COLO at Shanghai SF China Nov.15-17 2023![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)