How to choose pretreatment for powder coating?

Nov 15, 2019

1.Why you need pre-treatment before powder coating?

Pretreatment is used to remove oil, dirts, rust, stripping old painting layer, or smooth the surface, increase the coating film adhesion in order to get a better powder coating result. A good pretreatment allows the powder coating to better bond physically to the metal, withstand exterior weathering, and prevents flash rust prior to powder coating. Because of all the benefits associated with it, you should always consider adding metal pretreatment to your coating process.

2.What kind of pre-treatment should I use?

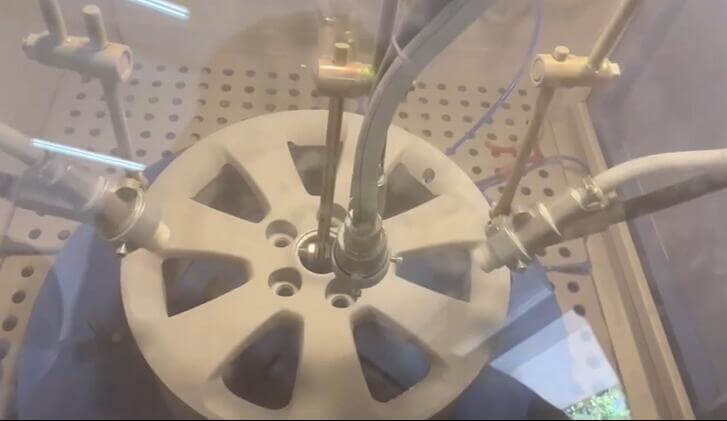

Blast Cleaning

Blasting with sand or shot is a great way to clean up metal scale, laser scale, rough welds, or heavily rusted steel. Blasting is also used to strip off previously coated metal for refinishing. While blasting smooths out a lot of surface defects in raw metal, it does not fully clean the metal of oils or other contaminants. Sandblasting machine or shot blasting machine is an ideal choice for small and medium workparts for personal workshop, such as wheel shops, car and motorcycle parts shop, as an enclosed blast cabinet is easy to place and use, requiring not big cost, and quite environment friendly.

Dipping Washing

Dipping powder coating pre-treatment is mainly used for the chemical reaction principle artifacts, workpieces in turn into the pretreatment tank, Base material react with tank liquid, grease, scale, dust on the surface of the workpiece and the clutter is clean, provide excellent corrosion resistance base material for final coating.Dipping washing is suitable for cleaning big or complex workparts, while the production capacity is not high.

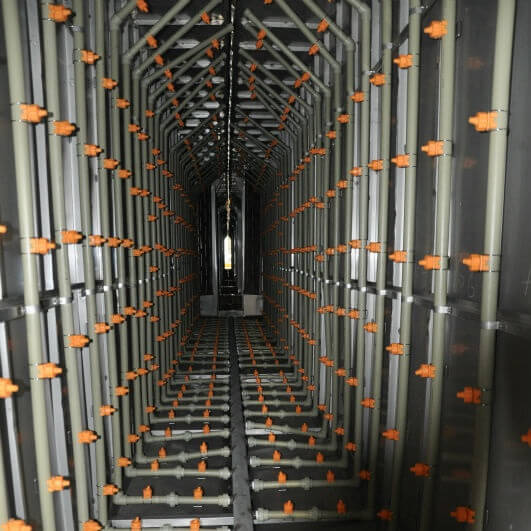

Spraying Washing

The spraying tunnel powder coating pretreatment is by using many spraying nozzles and circulation pump to spray chemicals onto the processed objects, it has multiple tunnel stages by using different liquids. This process is suitable for big production capacity requirement. The spraying tunnel normally requires 316L Stainless Steel to be fabricated, there for the investment is relatively high. Spraying preatment is often selected in a fully-automatic powder coating line.

The Pretreatment Choice Also Depends on Materials

First, determine what you’ll be coating the most often. If you are coating sheet steel, for example, you will usually only need light oil cleaning. Angle iron or castings often need sand/shot blasting to remove scale and surface rust. Aluminum is prepared differently than galvanized or regular steel; the oxidation layer of aluminum must be removed, which requires certain chemicals that provide a good etched layer for paint adhesion.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Nov 23, 2021

How to choose COLO powder coating machines?

Dec 02, 2019

How to choose a right powder coating recovery booth?

Nov 30, 2021

How to choose industrial powder coating ovens?![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)